Pick-up

×Neat, safe and convenient

The JUMBO’s wide pick-up combines clean and tidy collection without losses in a single pass with a supremely comfortable ride. It is suspended in the centre and controlled from both ends by a steel cam track. The enormous pick-up width of 2.3 mm according to DIN means that no swath is too wide. Thanks to the extremely high loading performance even swaths intended for a self-propelled harvester are cleanly picked up.

The large working width also makes driving into the swath and cornering easier, which takes the pressure off the driver.

Perfect ground tracking

Regardless of the terrain in which you use your JUMBO, the floating pick-up adapts perfectly to the ground contours and protects the crop against contamination.

Hydraulic adjustable weight alleviation reduces pressure on the ground to approx. 100 kg, allowing the pick-up to float over the ground.

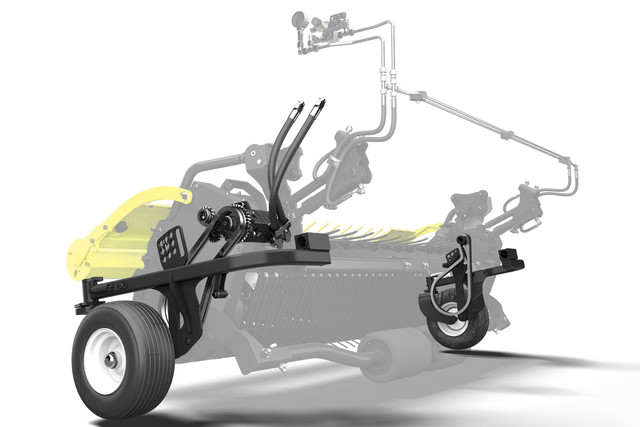

The optional pick-up jockey wheel chassis with floating function features a patented parallel linkage for unique ground tracking.

Controlled floating pick-up

The 7-row floating pick-up with a working width of 2.3 mm according to DIN ensures maximum intake. The JUMBO’s pick-up delivers clean and tidy collection without losses in a single pass.

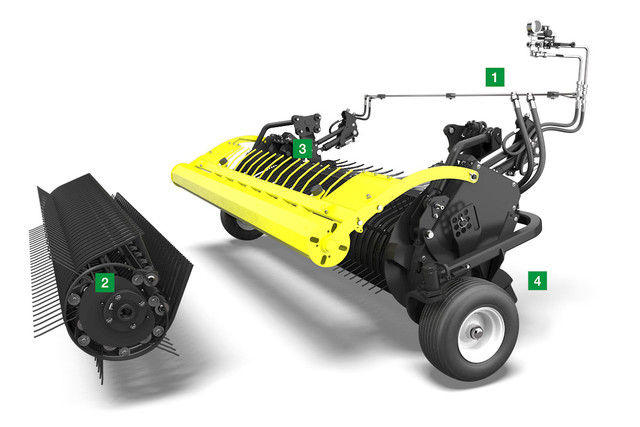

1 Hydraulic drive

The speed adapts automatically to the travelling speed in a range of 75 to 125 rpm.

2 Cam track control

Best quality forage is guaranteed not just by great reliability but also by cam track control. Compared to other commercially available systems, it allows significantly greater floating and can be used at markedly lower speeds.

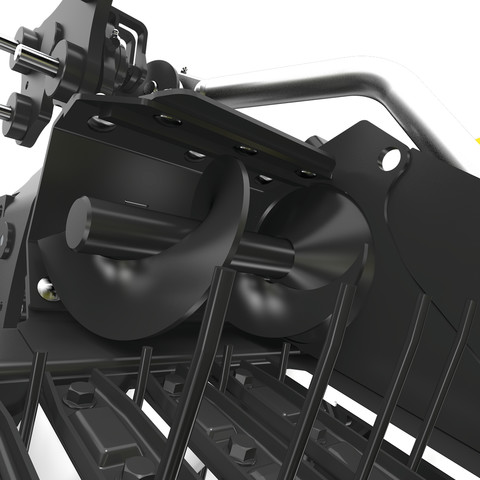

3 Actively driven feed augers

The feed augers deliver optimum crop flow even at high travelling speeds. The transfer throat is filled with maximum efficiency, thus increasing chopping quality.

Ground tracking

Large arc of movement of +/- 3.5 ° corresponds to vertical travel of 190 mm at the outer tine at both ends of the pick-up. The central suspension of the pick-up support frame and the two guide arms, one on each side, ensure perfect ground tracking.

4 Selectable jockey wheel linkage

The jockey wheel linkage can be adjusted depending on the application. You decide whether the pick-up should be coupled indirectly or directly.

Additional tracking roller

The additional tracking roller prevents the pick-up wheel from sinking into tractor wheel marks and enables unrestricted movement for best ground tracking.

190 mm arc of movement

With a vertical travel of 190 mm at each end of the floating pick-up, the JUMBO ensures perfect ground tracking and exact contouring.

The floating function allows you to collect the cleanest possible forage, even in difficult terrain.

Trailing jockey wheels

Standard

The standard trailing jockey wheels are implemented as rigid to guide the pick-up cleanly over every bump in the ground.

Outer width: 2.99 m

Hydraulically folding

To help drivers when access to a field is narrow the jockey wheels can optionally be folded in hydraulically from the control terminal.

The hydraulic folding trailing jockey wheel reduces the transport width at the pick-up to an outside dimension of 2.55 m.

Jockey wheel linkage

The standard trailing jockey wheels feature two jockey wheel linkages. This allows you to make adjustments to suit your particular set-up.

1Linkage position “indirect”

The raised jockey wheel is held at the same height as the pick-up tines, providing greater ground clearance.

2Linkage position “direct”

The jockey wheel transfers every movement directly (1:1) to the pick-up drum. This significantly improves ground tracking.

Jockey wheel chassis

The optional additional tracking roller prevents the pick-up sinking into tractor wheel marks. It is located on the centreline behind the pick-up and covers a wide area of ground thanks to its generous dimensions. Together with the two jockey wheels, the wide additional tracking roller forms a strong support triangle for perfect ground tracking. This considerably reduces the tines scraping the soil so contamination of the forage is avoided.

The additional tracking roller also guarantees clean forage collection in hilly terrain.

Hydraulic drive

The JUMBO pick-up’s new hydraulically adjustable drive system adjusts the speed automatically to the travelling speed. This ensures clean collection without dragging the forage through in the direction of travel.

This adaptation of the speed reduces crude ash ingress and protects the pick-up tines. The speed signal is received via the tractor’s ISOBUS signal, the tractor’s InCab port or direct from the loader wagon using an electronic brake system, electronic steered axles or intelligent trailed axles.

Pick-up speed is between 75 and 125 rpm. In automatic mode the pick-up regulates the speed independently. At a driving speed under 10 km/h the speed is only 75 rpm. It increases as loading speed increases. In manual mode the desired speed can be set individually.

Optimum intake angle

As the loading chamber fills up, the drawbar load applied to the tractor increases. This leads to increased compression of the rear tyres and takes the weight of the tractor's front tyres. As a result, the coupling point on the tractor tilts downwards, changing the angle between the pick-up and the rotor. An automatic control system constantly monitors the intake cross-section and compensates for deviations by raising the parallel lift drawbar. This means that the intake between the pick-up and the rotor always has the optimum cross-section.

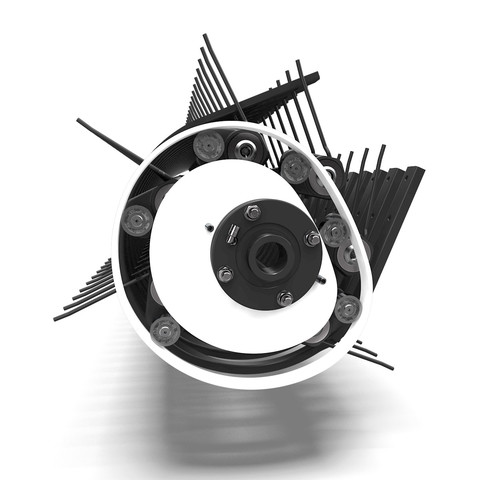

Cam track

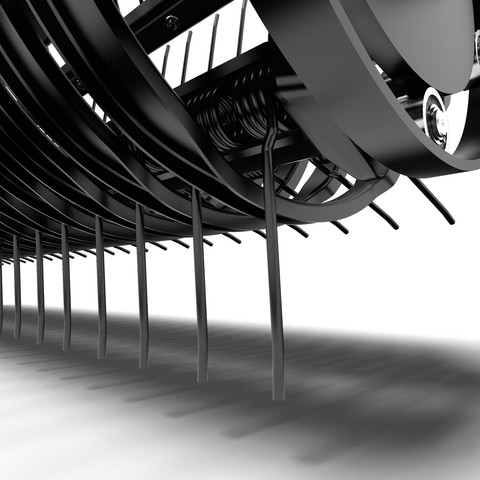

The shape of the cam track ensures optimum movement of the tines.

The tines, which are controlled in a sweeping arc, will only take up crop at the correct angle if they are guided by a cam track. They convey the crop gently upwards and actively transfer it to the rotor at a suitable speed.

The tine subsequently dips down at a right angle to prevent the forage from being drawn in.

Tines

The optimised DURASTAR pick-up tines with a wire thickness of 6 mm enable a 20 % longer service life with consistently high collection quality. This cuts wear costs.

Feed augers

Large diameter feed augers on each side actively merge the swaths. The compact swath is evenly distributed across the full width of the transfer throat as it is fed to the rotor. That is how the JUMBO achieves the best short chopping quality.

Handling trolley

For optimum maintenance and service access, the pick-up, with a rigid jockey wheel, can be placed on and removed from a handling trolley which is available as an option.

Removing the pick-up can reduce the JUMBO’s weight by approx. 520 kg for transport mode. This considerably increases the net load capacity. Combining it with an optional additional tracking roller can even save as much as 580 kg.

Removing the pick-up when the JUMBO is used purely for transport purposes also prevents it from being damaged.