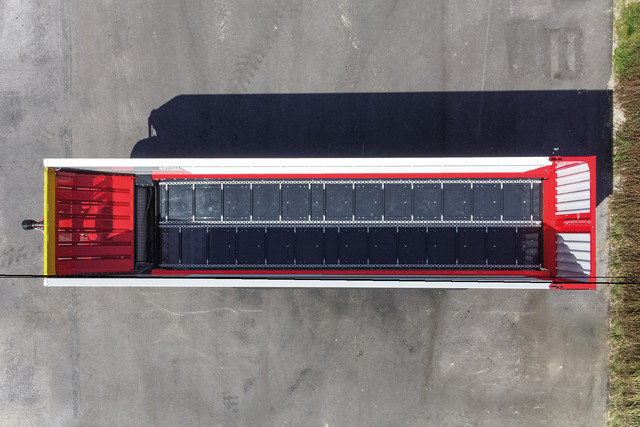

Loading chamber

×

Rapid unloading

The JUMBO’s excellent unloading performance makes it an efficient team player in any silage convoy. Its unloading speed of up to 35 m/min prevents vehicles used for rolling having to wait in the clamp.

Efficient unloading

Rapid unloading, a perfect blanket of unloaded material and as little work left to do by the rollers as possible, the JUMBO’s beater driveline makes it possible.

Unloading performance has been increased by a further 33 %. With total power output of 210 kW the beater driveline allows unloading times of less than a minute. This means that JUMBO models with a beater system have an output equal to those with no beaters.

The innovative form of beater rotor with V-twist work the crop evenly and with no power peaks. They reliably loosen even highly compacted forage. This saves energy and results in optimum efficiency with reduced wear.

The beater drive switch integrated into the angular gearbox is activated by the belt tensioner to ensure friction-locked startup. The soft start protects not just the beater driveline elements but also the scraper floor drive and the chains. No power peaks occur and the service life is prolonged.

If the selected feed speed is too high the scraper floor automatically slows down. Should an overload occur, a cam-type clutch protects the beater driveline.

The soft start means that unloading can be paused, enabling the crop to be split as it is unloaded in the clamp.

The evenly spread blanket of forage on the JUMBO facilitates the rollers’ work, thereby guaranteeing efficient compaction and the best silage quality.

Conical configuration

The loading area on the JUMBO has a conical form. On each side it opens out 25 mm to the rear. This keeps friction to a minimum during unloading. The loaded crop is released more quickly and the scraper floor speed can be increased earlier. This helps rapid unloading even when field to farm distances are long and the crop has settled.

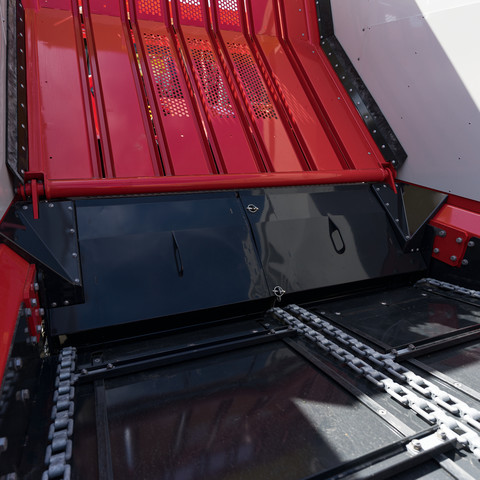

Lowered scraper floor

The scraper floor has been lowered by 250 mm. This reduces the amount of power required for loading. The higher forage package that goes along with this also allows increased compaction and the wagon increases its net load capacity.

As loading begins, a compact and stable forage block forms at the front panel. This is subsequently pulled continually backwards by the scraper floor.

The high-strength steel floor consists of panels and forms a strong loading area with minimal friction coefficients for rapid unloading.

Flat link chains

The wide flat link chains with a breaking load of 13 ton provide great stability, maximum reliability and smooth running. The scraper floor slats are double-bolted and rest on exchangeable guide bars.

Its high power transmission and robust construction make the JUMBO suitable for transporting all kinds of chopped material.

Scraper floor drives

Two high-performance drives with integrated 2-speed switching are integrated in the longitudinal bar.

The boost function ensures that all the tractor’s available hydraulic power is used.

Loading chamber expansion

By using 26,5" diameter tyres, loading chamber capacity can be increased by up to 2.6 m3 depending on the model. This makes full use of the legally permissible maximum overall height of 4 m and so increases cost effectiveness.

Load capacity expansion per model:

JUMBO 7380 DB / 8380 DB / 7400 / 8400: + 2 m3

JUMBO 7450 DB / 8450 DB / 7470 / 8470: + 2.3 m3

JUMBO 7520 DB / 8520 DB / 7540 / 8540: + 2.6 m3

Load containment system

The newly designed loading chamber cover quickly covers the load and secures it ready for transport on the road.

The large overlap area of the nets also secures loads that extend above the side panels.

The drive system is centrally mounted and compactly integrated in the wagon’s superstructure so that it is well protected.

Duct cover

An optional duct cover prevents crop from falling into the rotor duct while the wagon is being used for transport. 2-part design for easy handling.