CROSS FLOW

×

Swath merging without a conditioner

CROSS FLOW is a cost effective system for merging swaths. A cross flow auger is integrated in the mower unit to deposit the forage in the way you want it to be: Either merged as a swath, spread over the working width of the rear mower or as a wide swath to the side.

CROSS FLOW is available for the NOVACAT V 9200 and V 10000.

Cost effectiveness

CROSS FLOW works without a conditioner and is characterised by its light tare weight compared to conventional swath merging systems. This not only conserves the soil, but also saves fuel: In comparison to the cross conveyor belt system, with CROSS FLOW 20% less power is required.

The best forage

Dispensing with the conditioner means that your forage is handled with minimum impact. Thanks to the closed trough shape, the forage is transported directly from the sward to the swath. Dirt ingress is reduced to a minimum. In addition, disintegration losses are avoided. This provides optimum conditions for the best possible processing of plants that are rich in energy.

You can use the CROSS FLOW system in a variety of ways, both in grassland and for whole plant silage.

Maximum output

The auger has a diameter of 500 mm and is installed at a slight angle in the mower unit. This ensures optimum throughput. Even large volume crops and whole plant silage are placed in a tidy swath at a high output.

Scraper bars on the rear panel of the auger ensure blockage-free operation with a wide variety of forage conditions.

Driveline

The cross flow auger is operated by a robust V-belt drive. This withstands the toughest stresses, whilst ensuring a low weight.

The damping effect of the belts ensures smooth operation even with changing densities of crop.

The V-belt driveline also provides overload protection.

Convenience

For the highest level of convenience, the rear flap can be opened hydraulically from the comfort of the tractor seat as standard. This makes the system ideal for flexible applications.

The CROSS FLOW system is versatile in the range of applications that it offers to make your working day in the field a great deal easier.

Quicker drying

When the cross flow auger is open, the crop is turned into the flow of forage and spread wide, which accelerates the drying of the crop.

The rear flap can be opened hydraulically from the comfort of the tractor seat as standard. This makes the system ideal for flexible applications.

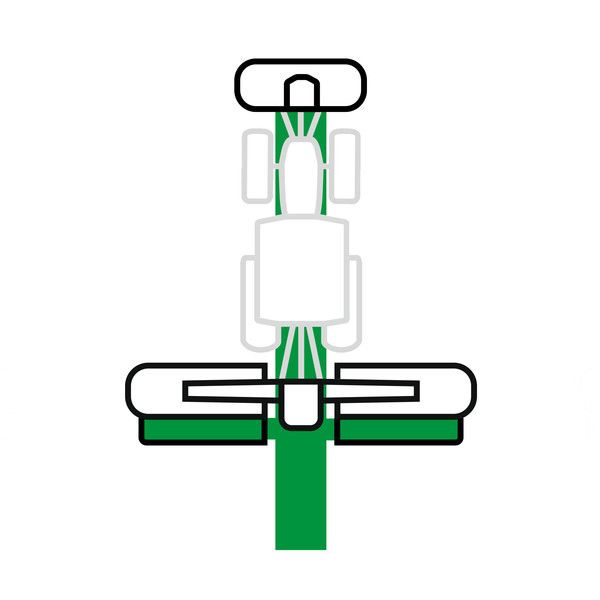

Wide spread placement

For a more intensive drying effect, open both rear flaps to place a wider and airier blanket of forage.

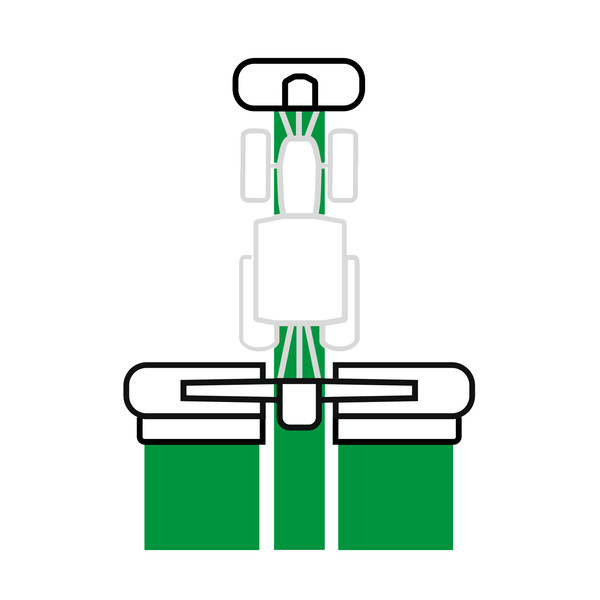

Swath placement for immediate collection

The swath is placed so that you can pick up and transport your forage away directly after mowing. This means that on hot summer days, for example, you can ensure that the crop does not dry too fast before you can harvest it.

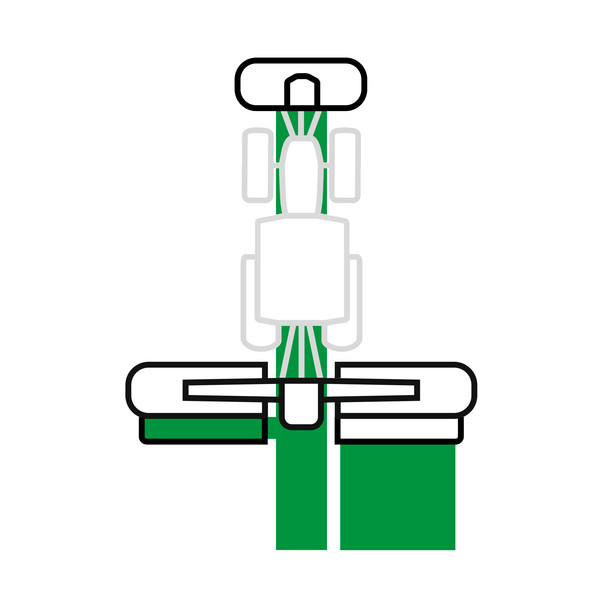

Intelligent swath placement

When the rear flap is closed on one side, the cross flow auger transports the crop from one mower to the centre of the swath of the front mower. As a result a loose and even swath is placed.

You can also mow around 19 m in two lanes, but place the two swaths within approx. 12 m. This is like the CROSS FLOW system taking care of some of your rake work. The perfect follow-up implement is a four-rotor centre-swath rake. In this way you can significantly reduce the number of passes and conserve the soil as well as your forage. You also save valuable time and fuel.

Intelligent mowing

When mowing along the field boundary, the cross flow auger can transport the crop to the inside. This is done with one rear flap closed. This ensures that your forage remains inside the field boundary during the subsequent tedding process.