Reliable components

×

Strong frame construction

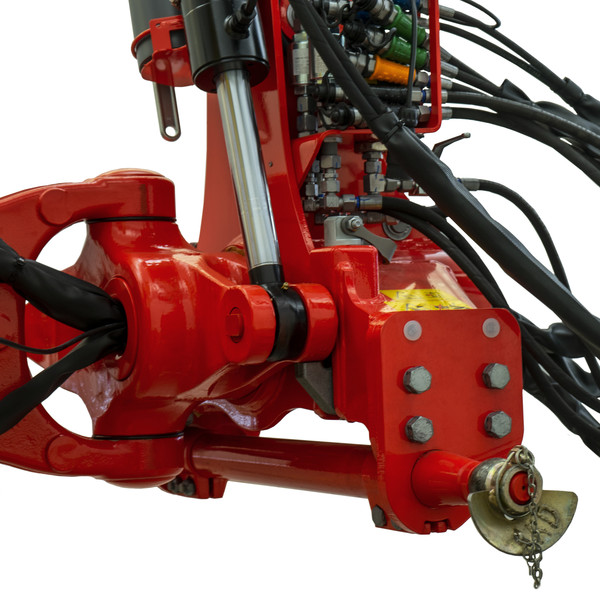

The plough beam has been engineered to absorb the loads acting on it during operation even better. The large dimension main beam section easily transmits the pulling force and is bolted on both sides. Loosening of the bolted connection is prevented by maximum pre-tensioning torque. To ensure the high strength of the beam, holes have been reduced to a minimum. In addition, the ingenious construction protects all bearing points and mounted components by reducing the forces acting on them.

Durable cast beam link

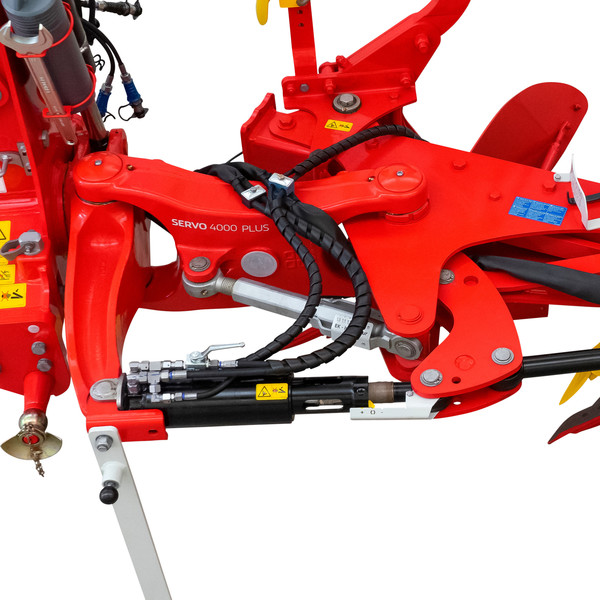

The beam link is made of high quality cast steel and is slightly curved. This ensures high strength and durability. The curved cast beam link provides more space for the front furrow to give the SERVO 4000 a wide range of front furrow adjustment.

Inside beam angle lift spindle

Because the spindle is on the inside, the beam angle setting is protected against contamination. It is designed as a closed beam guide with beam angle lift. The rotating spindle can therefore not collect dirt and is always ready for use. Easy adjustment is guaranteed at all times. Since the turnover cylinder rests on the beam angle lift when reversing the plough, it is not possible to distort the turnover unit.

Mechanical stone protection

To prevent overloading and possible damage, standard and PLUS models without NOVA stone safety devices feature expansion bolts. Easy changeover without jamming ensures you're back in action quickly after a furrow has been triggered. This saves time and increases output.