Tipos de rejas

×

Un cultivador solamente puede ofrecer su máximo rendimiento si los brazos están preparados para las condiciones más difíciles. Con las rejas de punta de diferentes durezas así como otras formas de reja como la reja estrecha, se cumplen todos los requisitos.

Para trabajar el suelo en toda la superficie, se puede elegir entre las distintas rejas de aleta con diferente dureza de desgaste.

Piezas de desgaste DURASTAR

Cada vez el tiempo de laboreo del suelo es más corto, y cada minuto productivo cuenta. Las piezas de desgaste DURASTAR y DURASTAR PLUS aportan una mayor vida útil de puntas y aletas gracias al material más duro.

Reja de punta CLASSIC

La reja de punta CLASSIC con un ancho de 80 mm convence por su terminación en punta con un buen comportamiento de entrada incluso en suelos muy duros. Gracias al extremo llano de la punta se forma un escaso agarre inferior entre la punta de la reja y las aletas adicionales montadas. Esta diferencia se mantiene a largo plazo también al desgastar la punta.

Reja de punta DURASTAR

La reja especialmente formada y cónica de 80 a 50 mm acabada en punta posee en las zonas principales de desgaste un mayor volumen de reja. Está hecho de materia base de alta calidad y garantiza una alta estabilidad a la rotura. Por la forma se consigue una reducida demanda de potencia de tracción con un buen efecto de mezclado al mismo tiempo.

La reja de punta va equipada con resistentes chapas de carburo de volframio. Estas aportan una larga vida útil y la conservación de la forma de la herramienta con un borde afilado en la punta de la reja. La casi constante forma de la herramienta asegura una profundidad de entrada constante y el ángulo de la reja queda sin cambios. No afecta ni al comportamiento de entrada ni al efecto de mezclado.

La parte delantera de la reja tiene una forma de escamas. Por esta forma, el contacto tierra-tierra reduce el desgaste por fricción y se cuida el material de atrás. En general se consigue una vida útil cuatro veces mayor con la reja de cultivador DURASTAR, dependiendo del suelo.

Reja de punta DURASTAR PLUS

La forma base de la punta de cultivador DURASTAR PLUS se parece a la reja de punta DURASTAR. El material base de la reja va protegido de forma todavía mayor por chapas de metal duro adicionales, desde el borde lateral de la reja hasta el centro de la reja. A mayores, el borde de la punta de reja va revestido completamente con recubrimiento de metal duro - ideal en condiciones pedregosas. Gracias a la prolongación hacia atrás se reduce el desgaste del material base detrás y la reja tiene un borde de corte afilado para una larga duración. Un comportamiento de entrada y una calidad de trabajo constante están garantizados.

En comparación con la reja de cultivador DURASTAR se consigue casi una doble vida útil. Las chapas guías van solapadas en la unión a la reja, para aumentar también su vida útil y mejorar el flujo de tierra.

Reja de aleta CLASSIC

La reja de aleta CLASSIC con un ancho de aleta total de 350 mm aporta un solape suficiente para un laboreo de toda la superficie. La aleta se monta en el soporte mediante un tornillo en dos posiciones diferentes. Así se ajuste el ángulo al suelo y se puede realizar un corte llano o un mezclado intensivo.

Reja de aleta DURASTAR

La resistencia de la aleta DURASTAR se aumenta con un recubrimiento térmico de partículas de carburo de volframio en la parte inferior a lo largo del borde de corte de la reja. El blindaje de la herramienta mantiene más tiempo la forma de la reja de aleta y resiste choques con piedras. Esto aporta una doble vida útil comparada con la reja de punta CLASSIC.

Reja de aleta DURASTAR PLUS

Con las chapas de metal duro en los bordes de corte se aumenta cuatro veces la resistencia de desgaste de la reja de aleta. La forma original de la reja se mantiene durante mucho tiempo garantizando un solapamiento seguro.

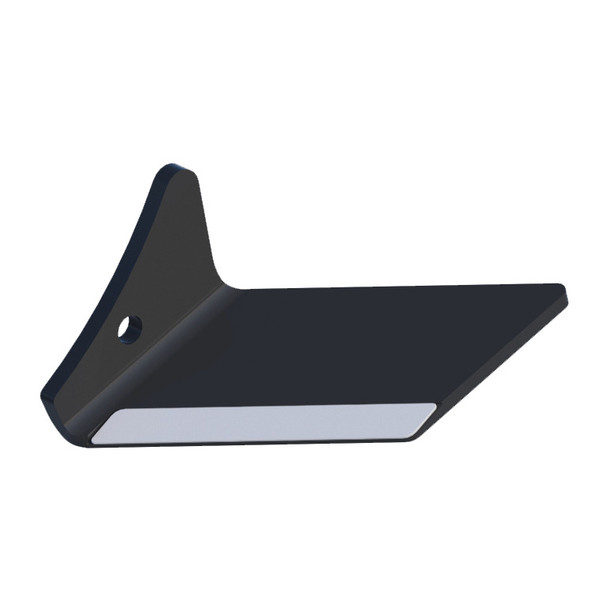

Reja estrecha DURASTAR

La reja estrecha DURASTAR de 40 mm está concebida sobre todo para un mullido profundo del suelo y para la rotura de compactaciones con escaso mezclado del suelo. Gracias a la reja más larga no hacen falta chapas guías adicionales. La punta de la reja va cubierta de metal duro. Esto aporta una entrada segura y una larga vida útil.

Al igual que las rejas de punta de la categoría de calidad DURASTAR y DURASTAR PLUS, parte de la parte delantera tiene forma de escamas. El material va protegido por el reducido desgaste de fricción por el contacto tierra-tierra.

Combinar individualmente

Según las condiciones del suelo y el laboreo que se desee hacer, se puede equipar el TERRIA con las herramientas adecuadas. Así las diversas rejas de punta con chapas guías se pueden combinar con las rejas de aletas en las diferentes categorías de calidad.