Best seed germination

Single-disc coulters and DUAL DISC double-disc coulters are available for planting cereals. PCS integrates precision seed drilling technology into a pneumatic seed drill, making you independent from single seed drills. This means greater flexibility and more cost efficient operation.

Single-disc coulters and DUAL DISC double-disc coulters are available for planting cereals. PCS integrates precision seed drilling technology into a pneumatic seed drill, making you independent from single seed drills. This means greater flexibility and more cost efficient operation.

| AEROSEM 3002 ADD | AEROSEM 3502 ADD | AEROSEM 4002 ADD | |||

|---|---|---|---|---|---|

| Working width | 3 m | 3,5 m | 4 m | ||

| Seed hopper volume | 1250 l | 1250 l | 1250 l | ||

| Row spacing | 15 12,5 cm | 12,5 cm | 15 12,5 cm | ||

| Coulter pressure (Maximum) | 50 kg | 50 kg | 50 kg | ||

| Transport width | 3 m | 3,5 m | 4 m | ||

| Filling height seed hopper | - | - | - | ||

| Number of rows | 20 24 pcs. | 28 pcs. | 26 32 pcs. | ||

| Coulter spacing (Front to rear) | 30 cm | 30 cm | 30 cm | ||

| Min. oil flow req. for fan | 35 l | 35 l | 35 l | ||

| Oil flowrate for PCS drive | 25 l | 25 l | 25 l | ||

| Weight with DualDisc | 1275 kg | 1430 kg | 1612 kg |

| Working width | 3 m |

| Seed hopper volume | 1250 l |

| Row spacing | 15 12,5 cm |

| Coulter pressure (Maximum) | 50 kg |

| Transport width | 3 m |

| Filling height seed hopper | - |

| Number of rows | 20 24 pcs. |

| Coulter spacing (Front to rear) | 30 cm |

| Min. oil flow req. for fan | 35 l |

| Oil flowrate for PCS drive | 25 l |

| Weight with DualDisc | 1275 kg |

| Working width | 3,5 m |

| Seed hopper volume | 1250 l |

| Row spacing | 12,5 cm |

| Coulter pressure (Maximum) | 50 kg |

| Transport width | 3,5 m |

| Filling height seed hopper | - |

| Number of rows | 28 pcs. |

| Coulter spacing (Front to rear) | 30 cm |

| Min. oil flow req. for fan | 35 l |

| Oil flowrate for PCS drive | 25 l |

| Weight with DualDisc | 1430 kg |

| Working width | 4 m |

| Seed hopper volume | 1250 l |

| Row spacing | 15 12,5 cm |

| Coulter pressure (Maximum) | 50 kg |

| Transport width | 4 m |

| Filling height seed hopper | - |

| Number of rows | 26 32 pcs. |

| Coulter spacing (Front to rear) | 30 cm |

| Min. oil flow req. for fan | 35 l |

| Oil flowrate for PCS drive | 25 l |

| Weight with DualDisc | 1612 kg |

| AEROSEM 3002 A | AEROSEM 3502 A | AEROSEM 4002 A | |||

|---|---|---|---|---|---|

| Working width | 3 m | 3,5 m | 4 m | ||

| Seed hopper volume | 1250 l | 1250 l | 1250 l | ||

| Row spacing | 15 12,5 cm | 12,5 cm | 15 12,5 cm | ||

| Coulter pressure (Maximum) | 25 kg | 25 kg | 25 kg | ||

| Transport width | 3 m | 3,5 m | 4 m | ||

| Filling height seed hopper | 196 cm | 196 cm | 196 cm | ||

| Number of rows | 20 24 pcs. | 28 pcs. | 26 32 pcs. | ||

| Coulter spacing Single disc coulter | 30 cm | 30 cm | 30 cm | ||

| Min. oil flow req. for fan | 35 l | 35 l | 35 l | ||

| Weight with disc shares | 1082 kg | 1239 kg | 1332 kg |

| Working width | 3 m |

| Seed hopper volume | 1250 l |

| Row spacing | 15 12,5 cm |

| Coulter pressure (Maximum) | 25 kg |

| Transport width | 3 m |

| Filling height seed hopper | 196 cm |

| Number of rows | 20 24 pcs. |

| Coulter spacing Single disc coulter | 30 cm |

| Min. oil flow req. for fan | 35 l |

| Weight with disc shares | 1082 kg |

| Working width | 3,5 m |

| Seed hopper volume | 1250 l |

| Row spacing | 12,5 cm |

| Coulter pressure (Maximum) | 25 kg |

| Transport width | 3,5 m |

| Filling height seed hopper | 196 cm |

| Number of rows | 28 pcs. |

| Coulter spacing Single disc coulter | 30 cm |

| Min. oil flow req. for fan | 35 l |

| Weight with disc shares | 1239 kg |

| Working width | 4 m |

| Seed hopper volume | 1250 l |

| Row spacing | 15 12,5 cm |

| Coulter pressure (Maximum) | 25 kg |

| Transport width | 4 m |

| Filling height seed hopper | 196 cm |

| Number of rows | 26 32 pcs. |

| Coulter spacing Single disc coulter | 30 cm |

| Min. oil flow req. for fan | 35 l |

| Weight with disc shares | 1332 kg |

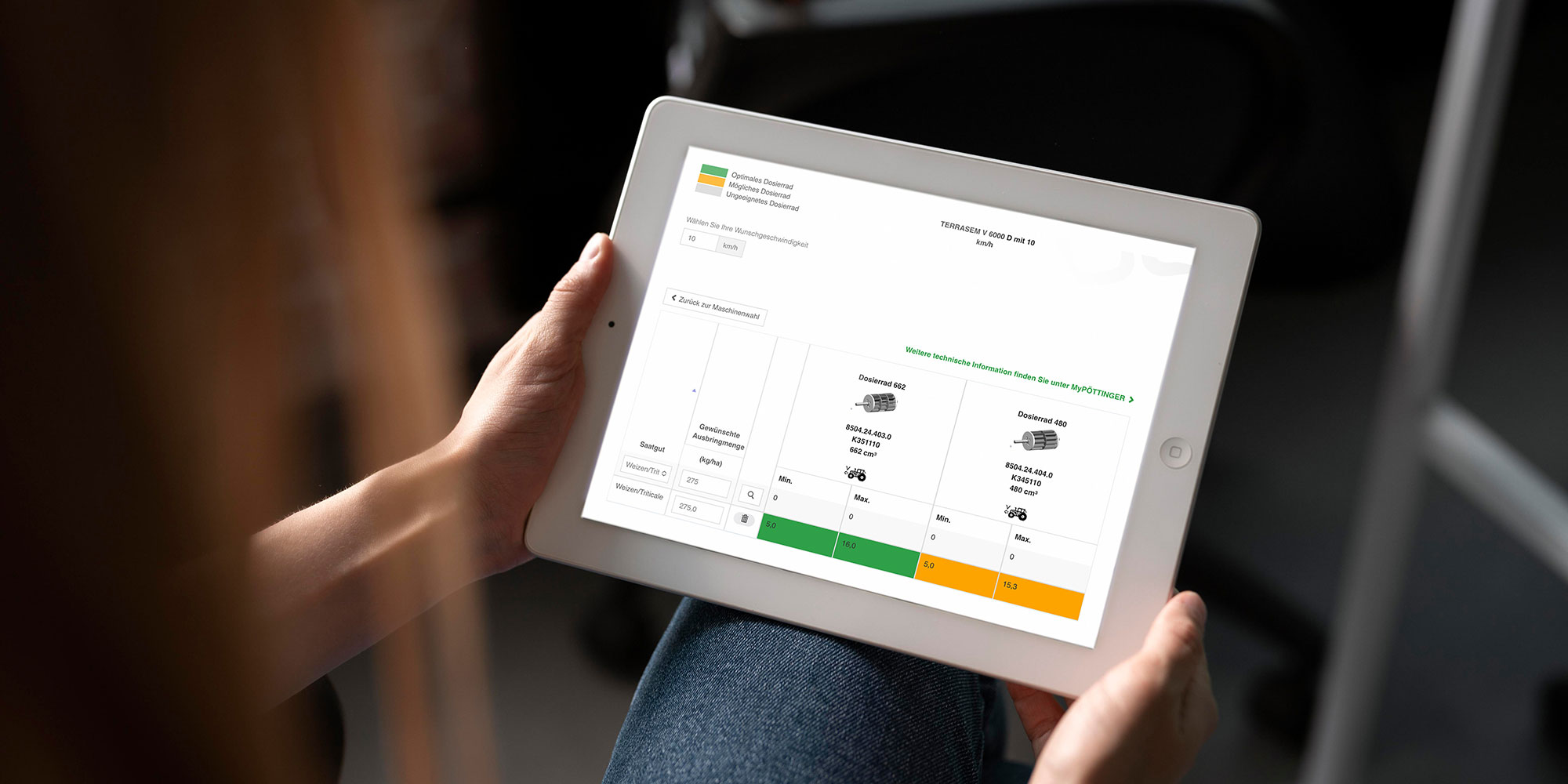

Choose the right metering wheel for your seed material simply by using METERING WHEEL ASSIST on your smartphone, tablet or PC. Get the new app from the App Store now (for iOS operating systems).

To the METERING WHEEL ASSIST app: https://www.poettinger.at/metering-wheel-assist/

To the iOS app: https://itunes.apple.com/de/app/p%C3%B6tsem/id1434048370?mt=8

To set up the optimal tramline system, you need to synchronise your machinery. TRAMLINE ASSIST helps you to do this. When choosing your seed drill, parameters such as the working width of your crop care machines, track and tyre widths are critical for optimising tramlining. TRAMLINE ASSIST identifies the tramline rhythm for you, the position of the tramline rows, and the number of rows that need to be switched off.

![Animation IDS [english] Animation IDS [english]](https://i1.ytimg.com/vi/o4RYHZKkOFY/mqdefault.jpg)

![PÖTTINGER AEROSEM Pneumatic seed drills [english] PÖTTINGER AEROSEM Pneumatic seed drills [english]](https://i1.ytimg.com/vi/-k7sCRuvqA8/mqdefault.jpg)