The multi-purpose rotor loader wagon by PÖTTINGER is celebrating its 25th anniversary.

The JUMBO is a high-performance silage wagon, renowned for its maximum efficiency, outstanding operational safety, and superior comfort. It ensures work that is both enjoyable and yields high returns. The new series confidently navigates the harvest season and serves as an ideal companion for transporting various goods even beyond the season.

Then, as now, the principle remains the same:

Whether you’re a farmer or a contractor, investing in premium feed always pays off. For long-term customer loyalty and new acquisitions, focusing on the highest feed quality is equally beneficial for contractors and feed suppliers.

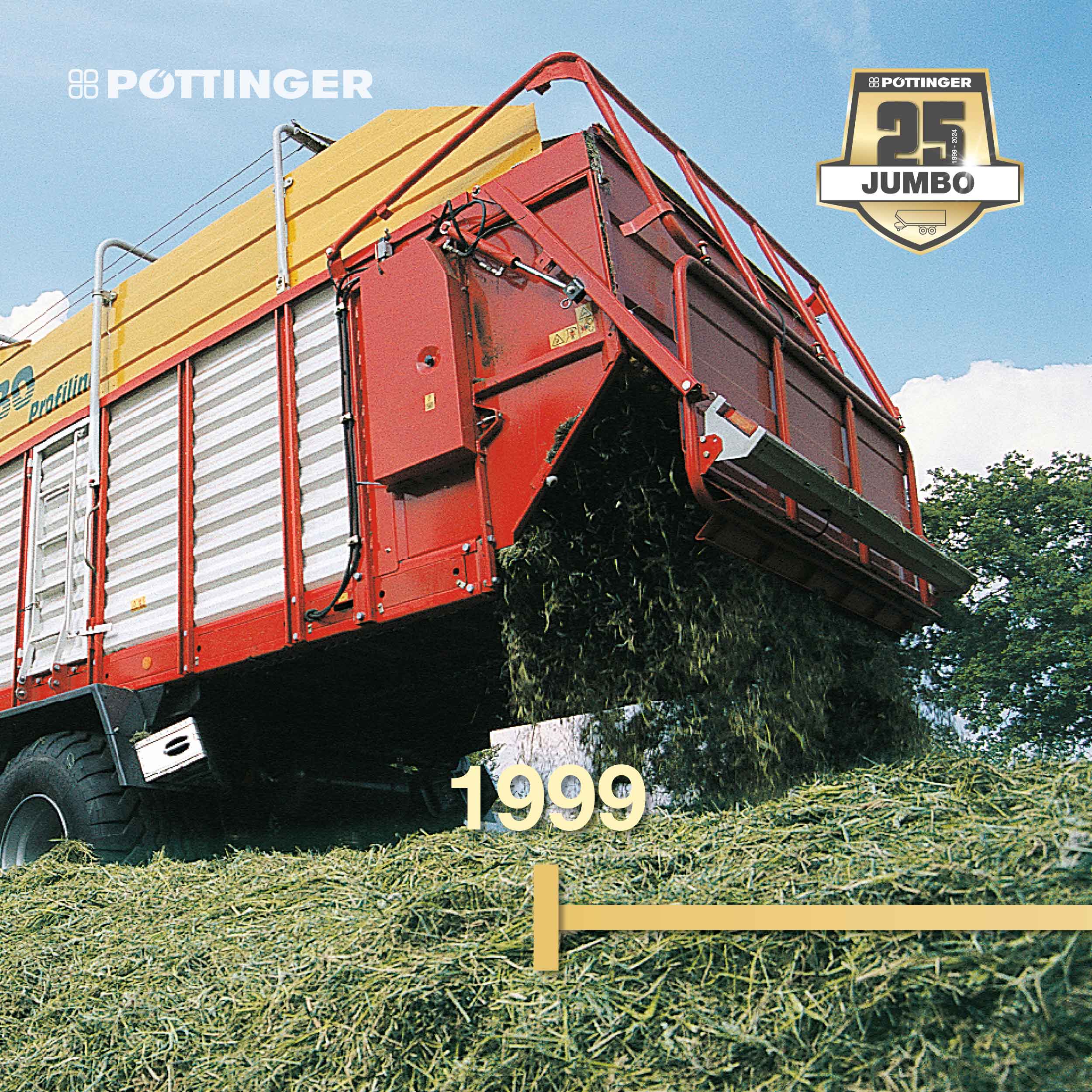

The very first JUMBO was unveiled to the world in 1999, revolutionising high-performance silage harvesting. Back then, it was hailed as “The new dimension of large-capacity silage wagons” and stood as the first and only system to challenge the emerging field chopper

The high-performance class

Choose the right JUMBO for your business!

The evolution of the JUMBO loader wagon

25 years of experience and development have also brought many innovations.

EASY MOVE

The EASY MOVE swing-out knife bank has been designed to enable ergonomic working. 🙌 By swivelling the knife bank out by 90° to the side of the wagon, the knife bank can be cleaned easily and the knives can be changed effortlessly - no bumping your head, no crawling under the loader wagon in a crouched position.

👉 The EASY MOVE knife bank swivelling system was awarded the silver medal for its innovative technology at Agritechnica 1999 and continues to offer the highest level of operating comfort and the simplest maintenance. 🥈

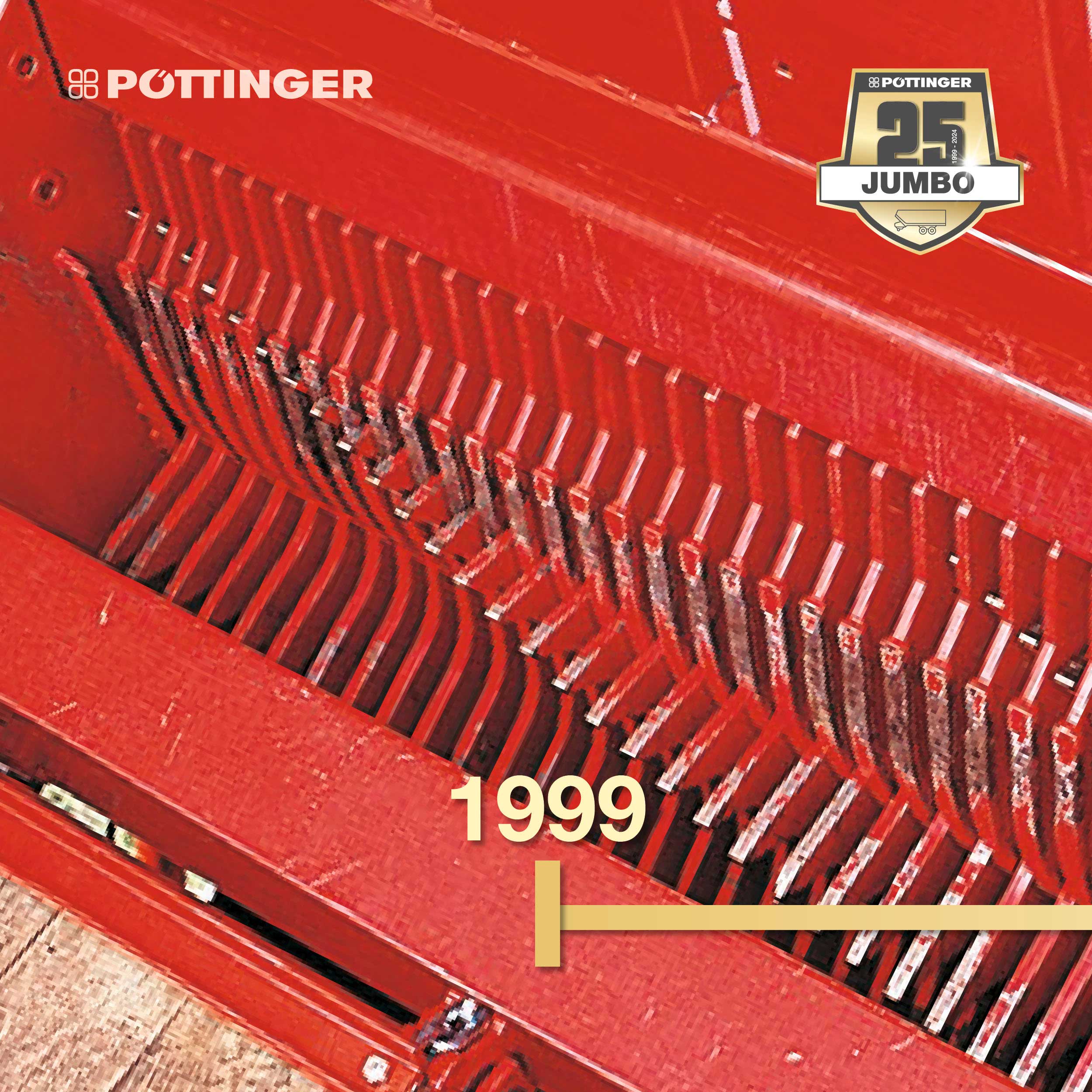

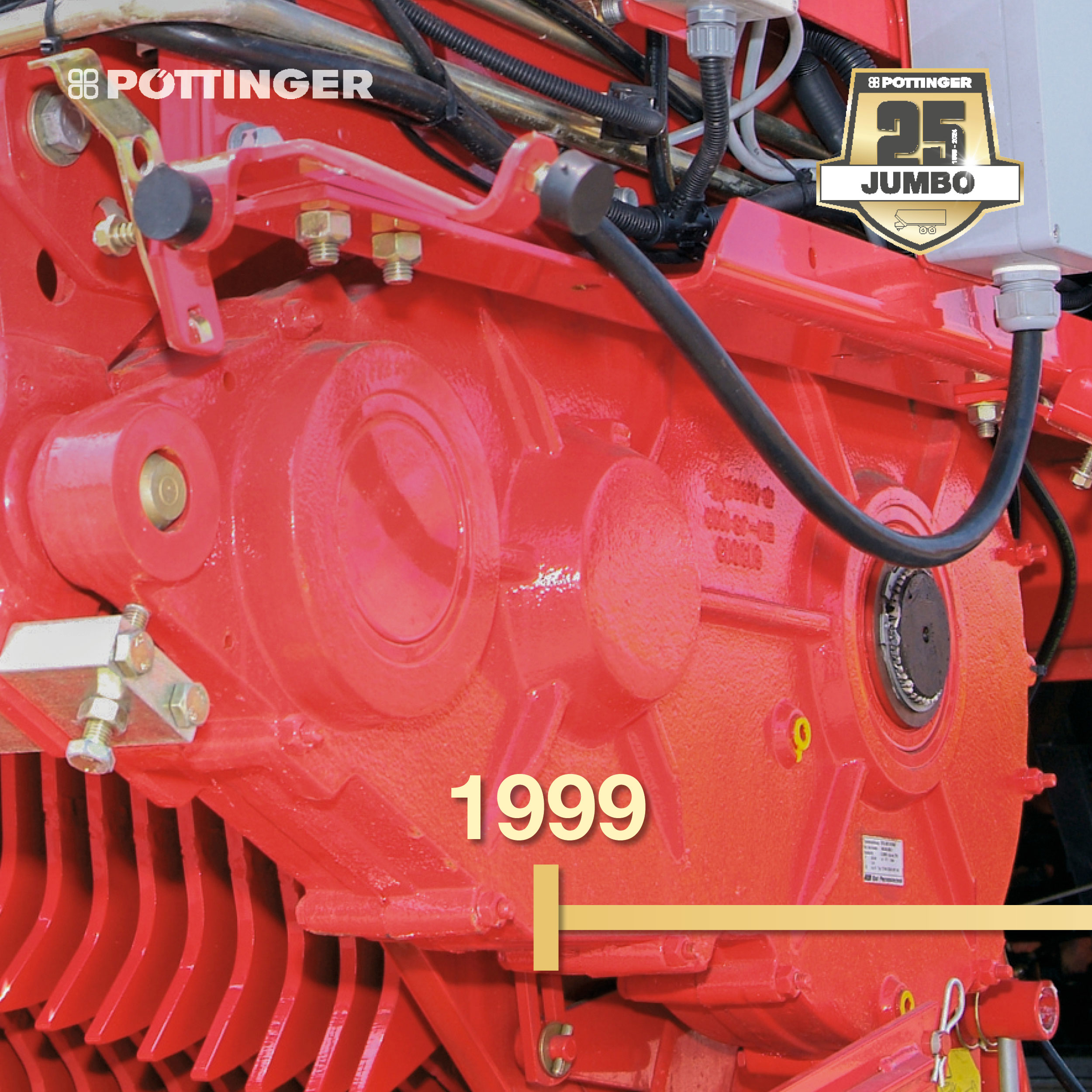

Beater rotors

The beater rotors on the JUMBO were used from the beginning to loosen the crop and ensure consistent unloading so that the forage could be well compacted in the clamp. 🌱🌿 In 1999, the beater rotor driveline was fully enclosed for protection and routed along the right-hand side of the wagon. 🧐 Two heavy-duty angular gearboxes and a chain transmitted power to the beater rotors.

✔Thanks to the next stage of development - smooth start-up of the drive train with a Powerband - the beater rotors can also be engaged under full load. 🙌 The hexagonal cross-section beaters have also been improved over the years, so the V-shaped configuration of the aggressive tines effectively loosens the compacted material during unloading. 👏

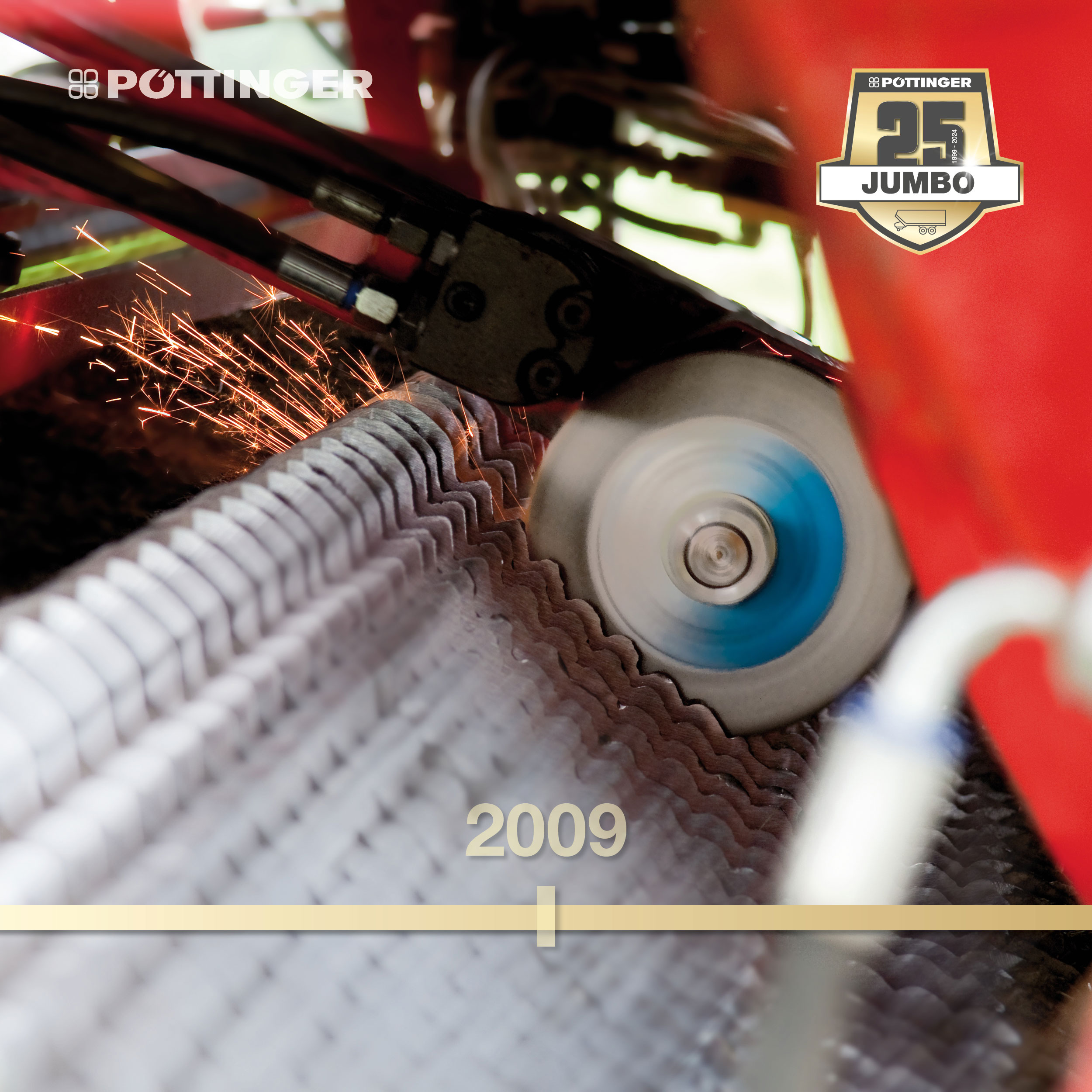

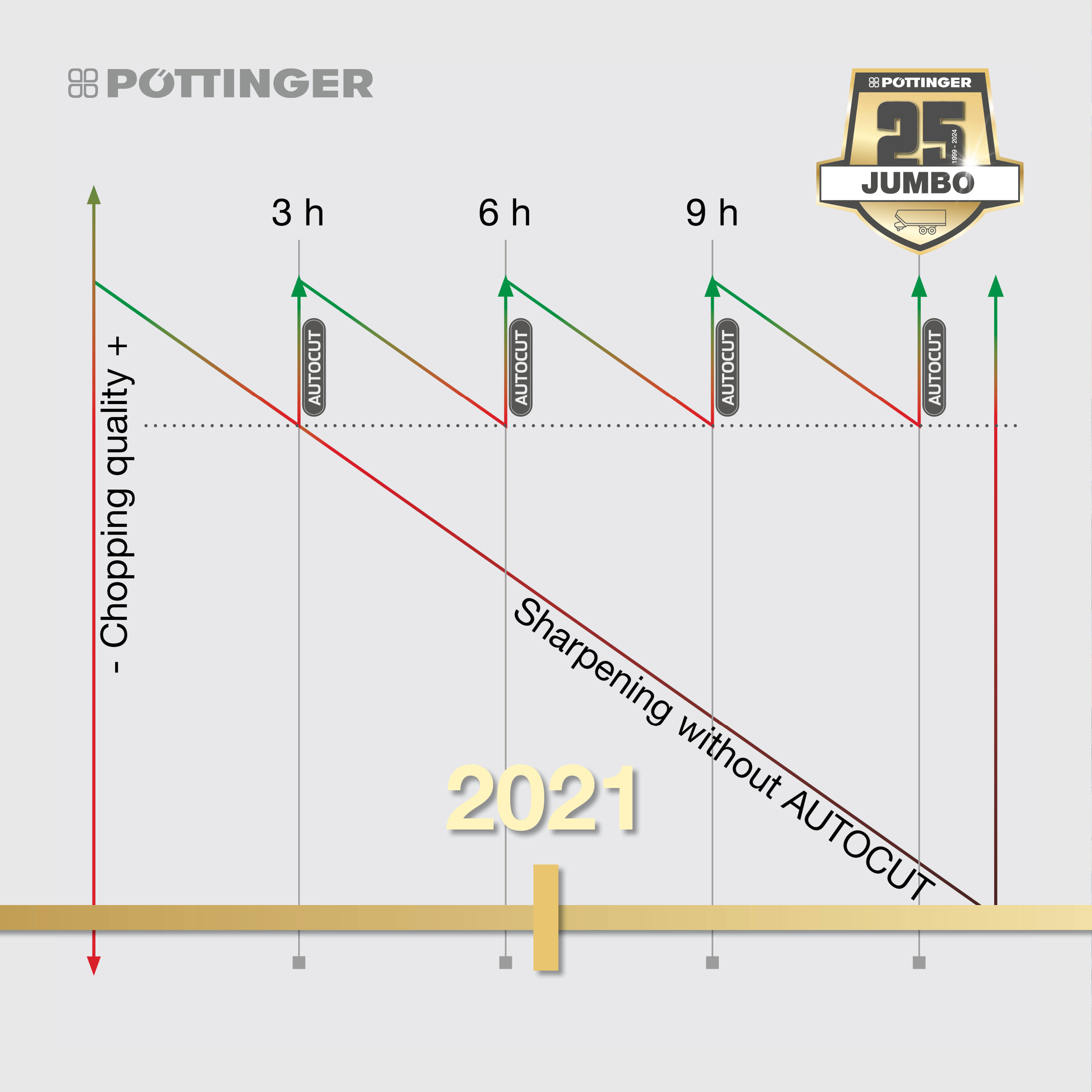

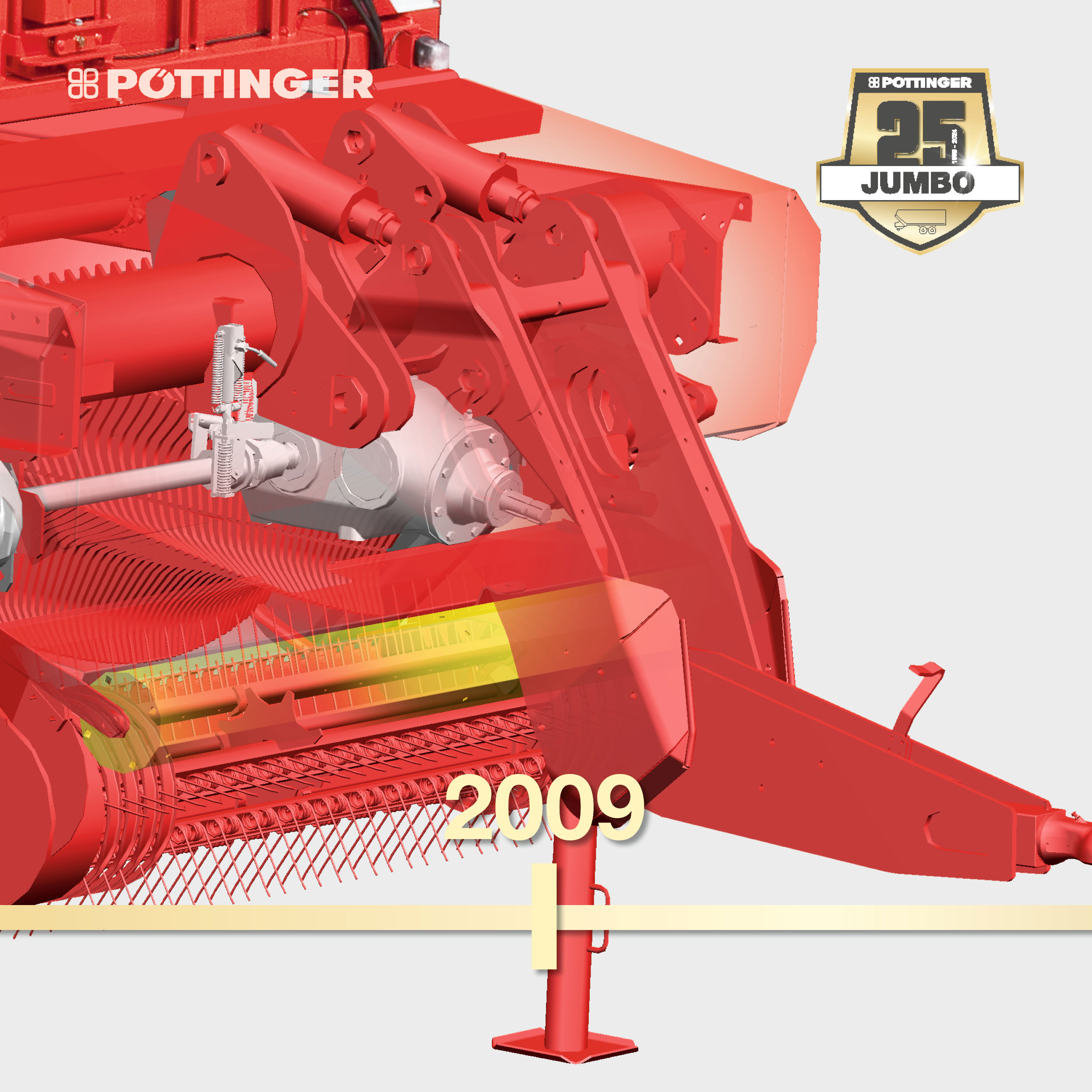

AUTOCUT

A precise and consistent chop is the basis for the best silage quality. AUTOCUT is a fully automatic knife sharpening system that ensures consistent chopping quality throughout a whole working day. 🌱🔪 PÖTTINGER launched the first fully automatic knife sharpening system under the name AUTOCUT in 2009, at the same time as the 1010 series loader wagon. In the same year, this feature was awarded the Silver Medal for Innovation at AGRITECHNICA. Back then, as now, the sharpening sequence is carried out quickly and easily during a short break by simply pressing a few buttons. 👌

✔ Thanks to the permanently sharp knives and the electric-hydraulic drive system, fuel consumption is reduced by up to 15 % and maintenance time is reduced by 45 minutes a day.

Rotor

The key component on the JUMBO is the loading rotor. As the heart of the machine, its robustness and performance are what stand out. 🙌 The rotor and its gearbox deliver high output chopping and compression. 🌱🔍

At the beginning of the JUMBO era, the rotor with eight rows of tines arranged in a spiral had a diameter of 800 mm. Today, the rotor has a diameter of up to 850 mm and is even more powerful. 💪 The removable tines feature has been discarded on the new rotor and the rotor tines now have optimised geometry. ✔ As a result, increased durability is guaranteed, due to the combination of the large scraper surfaces in the loading chamber and the best possible compaction of over 400 kg/m³, service life has been extended by 25 %.

Pick-up

The pick-up is responsible for the clean and tidy collection of the crop. 🌱 At first, the JUMBO series had a pick-up that was 2,000 mm wide, with six rows of tines, and a height-adjustable wind guard. In 2012 ground tracking was taken to the next level thanks to the pick-up with a jockey wheel chassis. Since then, the JUMBO has been available with a Super Large pick-up. 🙌 2021 saw an upgrade to seven rows of tines, which was then followed by a hydraulic driveline added to the pick-up on the JUMBO 7000 and 8000, with a standard pick-up width of up to 2,300 mm. In 2024, the transfer plates were optimised, and on the JUMBO 5000 you can choose between the 6-row all-rounder pick-up, or the 7-row Profi pick-up.

👉 Today, JUMBO pick-ups have a freedom of movement of 170 mm (JUMBO 5000) and 190 mm (JUMBO 7000, 8000).

Front panel

In 2008, the originally rigid front panel on the JUMBO 1000 series was made a little more flexible on the JUMBO COMBILINE. The 3-function front flap could be moved hydraulically into three different positions. As a result, the front panel was designed to switch between loader wagon and harvest transport mode while providing an excellent view into the loading chamber. This allowed the loader wagon to be utilised more flexibly depending on the harvesting scenario. 👌🧐 Since the JUMBO 7000 and 8000 series, there has been a movable, smart front panel. This is angled diagonally to the front and offers an additional volume of 4.3 m³ with the same length of loader wagon. 🙌

Das Abladen

The unloading process on the JUMBO DB has continuously improved over the past 25 years. Today, the loader wagon unloads and distributes the harvested crop more quickly and uniformly thanks to the beater rotors. The forage is also loosened again during unloading before it is compacted in the clamp. 🌱

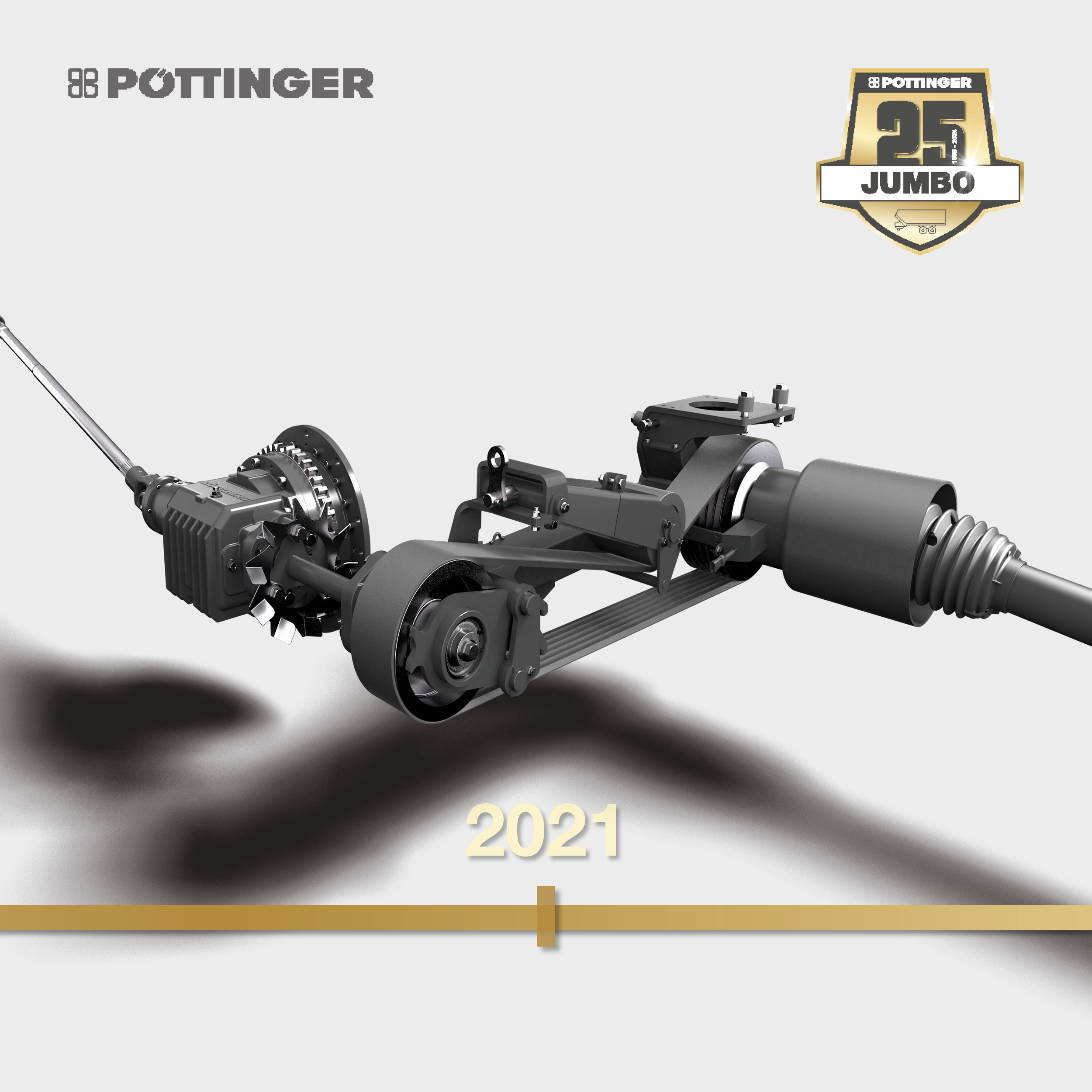

Der Antrieb

The driveline of the JUMBO series has seen some changes with respect to both its construction and its output. 🌱 In 1999, the JUMBO was designed for tractors with up to 280 hp. Today, the 7000 and 8000 series can be powered by tractors with a maximum of 500 hp. 🚜 Additionally, overload protection was increased from 2,000 Nm (1999) to 3,000 Nm (JUMBO 7000) and 3,500 Nm (JUMBO 8000). The decision was taken to remove the overload protection from the PTO shaft and integrate it directly in a fixed position in front of the angular/planetary gearbox.

👉 Now, the driveline has a double wide-angle PTO shaft without a clutch and is powered by a Powerband to deliver maximum power transfer in all operating conditions.

Our customers report

Our customers have also always been enthusiastic about JUMBO technology.

Multiple test comparisons

Every JUMBO series has been tested in independent comparisons, from the loading unit to the drive. Here we show a few of the test comparisons for you.

PROFI 09/2022

"A real harvester wagon"

"With 65 knives and a theoretical chopped length of 25 mm, the new JUMBO 8000 short chop loader wagon from Pöttinger can compete with the forage harvester. It's a real harvester wagon."

"The new Autocut system is controlled electrically instead of hydraulically. It is faster and more precise. You can operate the entire system from the side keypad without getting your hands dirty."

Traction 02/2022

"Austria's premium class"

"With its three axles and 54 m3 load volume, the JUMBO is an imposing sight."

"Thanks to the movable front panel and scraper floor with boost function, the crop is in the clamp in no time."

"These wagons are versatile, deliver a clean result and can be loaded and unloaded quickly thanks to the movable front panel."

PROFI 08/2021

"Eats more, compacts more"

"The latest one is out of the bag: belt drive, pivoting front panel and loads of capacity."

LANDWIRT 14/2021

"The JUMBO with a smart front panel"

"The manufacturer has redesigned all the core components to handle tractors up to 500 hp."

PROFI 10/2009

"Pöttinger's Jumbo Combiline wagon impressed us with its efficient, easy-to-use loading system, …"

"45 knives, 34 mm chop lengths and excellent accessibility – the high-output Jumbo cutter."

PROFI 02/2008

"A powerful, high-capacity multipurpose wagon"

"The JUMBO Combiline impressed us during the test with its high-performance and user-friendly loading unit. The stability of the superstructure and the handling on the road and in the field of the high-performance wagon impressed the test drivers, as did the ease of switching between loader wagon mode and harvest transport mode."

PROFI 09/2001

"The silage eater"

"A chopped length of just 34 mm ... no one can match the JUMBO from PÖTTINGER."

"The swing-out knife bank is very practical."

The competition - YOUR favourite JUMBO moment

Thank you for the many entries for the best JUMBO moment competition of the last 25 years! The 25 JUMBO prizes have already been sent to all the winners. We hope you enjoy them.