For half a century, PÖTTINGER agricultural technology has stood for innovation, passion and reliability in arable farming. What began in 1975 with the takeover of the Bavarian Plough Factory in Landsberg am Lech, Germany, has developed into an impressive success story. It is a story that is packed with pioneering innovations and future-focused decisions. Today, PÖTTINGER is one of the leading providers of agricultural machinery for both grassland and arable farming. Together, we are proud to look back on 50 years of experience and ongoing development. And in the future, we will continue to set the standards for sustainable and efficient agriculture.

The success story

Our journey to becoming an arable farming specialist began in 1975 with the purchase of the Bavarian Plough Factory in Landsberg am Lech. This strategic step laid the foundation for our focus on arable farming.

Founded in 1891, the Bavarian Plough Factory was one of the oldest manufacturers of soil preparation implements in Germany. Following the takeover, in addition to acquiring 85 years of experience, we also gained the expertise to develop high-quality arable farming machines.

During the next few years, we launched a large number of innovative and future focused machines:

Our innovations are progress that sets standards

Our innovative spirit and ongoing development make us an agricultural technology specialist, and our machines are the ideal tool in arable farming. Our story features numerous unique developments that make everyday work easier for our customers. From introducing the innovative control centre on ploughs and optimising seed drill technology to achieving maximum flexibility in hoeing technology, our machines are packed with impressive features that are well thought-out and help to get the job done effectively and efficiently.

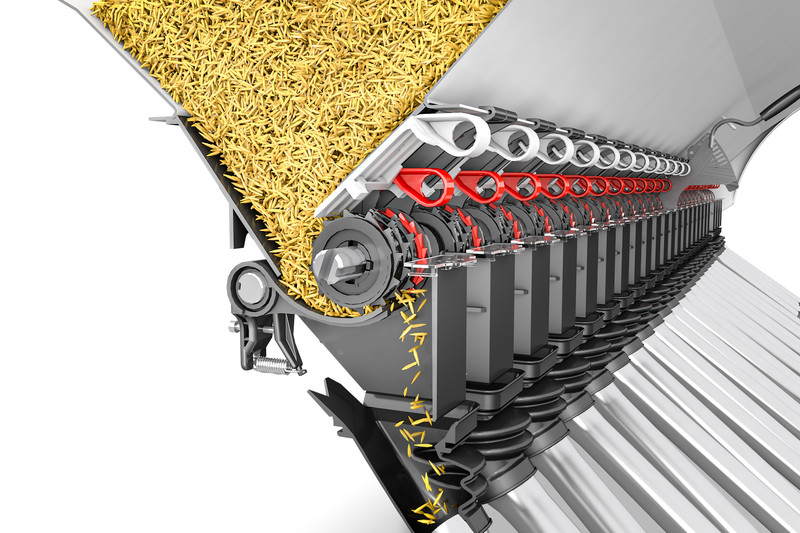

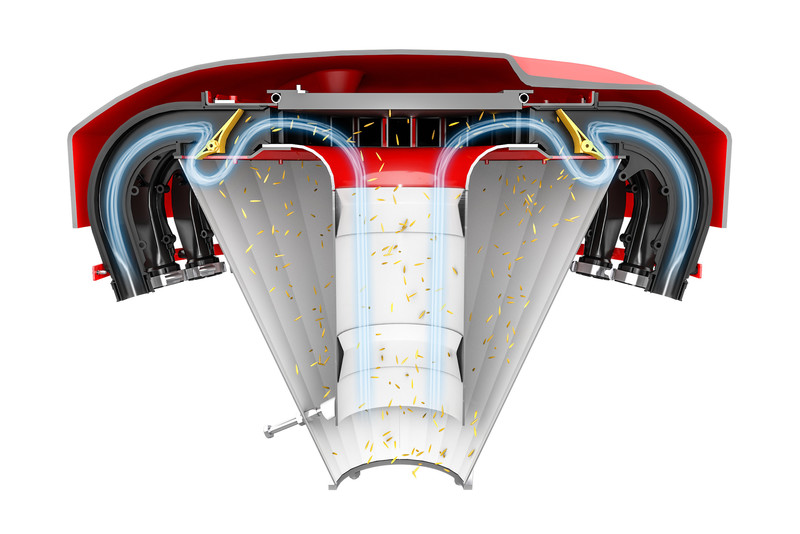

TERRASEM: Multiple sowing processes

Customer testimonials

At PÖTTINGER, we stand for quality in all areas. However, nothing speaks more clearly in favour of the performance of our machines than the many years our customers have been using them. At the same time, because our customers have the highest expectations, it is from them that we get the most critical feedback. Farmers from all over the world report on how our machines and technology make their day-to-day work easier and maximise their yields. Find out why they choose to rely on PÖTTINGER machines. Their success stories motivate us every day and prove the quality of our products.

SERVO 3000 P: "Weed control and seedbed preparation made easy"

"We plough almost all our fields, except for ryegrass. Ploughing lets us prepare the seedbed better and makes weed control easier. For cereals, we plough the field and then sow the seed directly afterwards. For maize, we prefer winter furrows, especially on difficult soils. The SERVO 3000 plough is equipped with hydraulic furrow width adjustment, which makes it easier to finish along the edge of the field and at headlands.

Compared to the higher power ploughs from PÖTTINGER, I decided in favour of the SERVO 3000 because it matches my tractor better. One of the biggest advantages of this 6-furrow plough is its manoeuvrability, because it is relatively short."

Samuel Soudain

Farmer

Bécourt, Pas de Calais | France

SERVO 4000 P: "For healthy forage"

"For me as an arable farmer and pig breeder, ploughing is still a priority, because I want to ensure there are no toxins in the forage. Especially after harvest maize, I believe that the straw should be ploughed in properly to avoid fusarium in the wheat.

That's why I decided to go for the SERVO 4000 P with hydraulic furrow width adjustment and the hydraulic depth wheel. I especially like the excellent surface finish to the soil, the strength of the plough, and how easy it is to adjust."

Gerhard Neubauer

Farmer

Thalheim bei Wels | Austria

SYNKRO 4030 K: "Regulating the water balance"

"In spring, we have to take care of the water balance, and the SYNKRO allows us to work shallow enough to keep valuable water in the soil.

Erosion control is also an important issue, and the CONOROLL rear roller creates the best soil structure for preventing erosion when it rains."

Katharina Huber

Farmer

St. Margarethen | Austria

AEROSEM 4002 FDD: "Wide range of applications"

We opted for the AEROSEM F for several reasons. Firstly, the pressurised hopper with dual metering gives us the flexibility we need in wet years to sow oil seed rape and deposite slug pellets at the same time. And secondly, the coulter rail with DUAL DISC coulters offers the reliability of precision drilling, even if there are still maize residues on the soil surface. The distribution head is also a major advantage for us. We have sown wheat, oil seed rape and ryegrass so far, and the seed emergence is very good, everything positive so far."

Christian Vijverberg

Farmer

Etain, Meuse | France

TERRASEM V 6000 D Z: "A versatile machine"

"The FERTILIZER equipment is the big advantage that I was looking for. It makes the machine very versatile and is perfect for my farm business. The working results are always very impressive. And above all, the number of hoppers in combination with the TEGOSEM allows me to carry out multiple applications. That was exactly what I was looking for to reduce the number of passes. This is a very important aspect, especially in terms of my contracting business."

Jean-Michel Protain

Farmer and contractor

Isse, Marne | France

TERRASEM V 4000 D: "Optimal soil cultivation and no crabbing"

"We have soils that vary a lot, from light to heavy. We sow most of the crops using min-till mulch drilling. That's why we decided to go for the TERRSEM V 4000 D. The strength of this machine lies in the X configuration of the disc harrow. As a result, there is absolutely no sideways pull and it cultivates the soil perfectly."

Piotr Szymanski

Farmer

Dobropole | Poland

TERRASEM V 6000 D Z: "Reliable and easy to use"

"We have two TERRASEM seed drills in operation. Because we farm more than 14,000 hectares, it is important to us that the machine is easy to operate and reliable. With the latest generation of TERRASEM, all the settings are done conveniently using the terminal so you only need to leave the cab for calibration. All the parameters are displayed on the screen and can be adjusted in real time. Sowing quality is consistent and there are two additional options for applying fertiliser, which is very important to us in the current environment."

Igor Kunitskyi

Farm Manager DP Agrofirma Luga-Nova

Oblast Wolhynien | Ukraine

ROTOCARE V 6600: "Versatile with a high output"

"During the first season, we have already covered around 200 hectares. Among other things, manure from the barn and chicken sheds was incorporated. Before reseeding the pumpkin crop, we loosened the rain-hard soil. We really like the maintenance-free and simple operation of the machine. We definitely recommend the ROTOCARE, because its range of uses is much wider compared to a conventional tine harrow. Being able to drive at high speed means that it achieves a very high output."

Thomas Hagenauer

Farmer

Dobersberg im Waldviertel | Austria

FLEXCARE V 9200: "Flexible in operation"

"We have been using the FLEXCARE on our farm for two years to incorporate liquid fermentation residues and for controlling weeds early on. In 2023, we hoed 500 hectares of maize with the FLEXCARE. We particularly appreciate the flexibility of the hoe. The individual shares can be easily adjusted and removed. What's more, the camera system works very well, even in different crops, high levels of airborne dust, or if the sun is low on the horizon."

Anica Hauptmann

PAE Marktfrucht GmbH

Putlitz | Germany

You can find more customer testimonials here:

YouTube Playlist customer stories