Mulch drilling offers a number of advantages for arable farming. Reduced tillage saves fuel and working hours. The TERRASEM universal seed drill combination with integrated tillage tools makes it possible to combine the steps of seedbed preparation and sowing, saving valuable time in the process. In addition to the cost savings, mulch drilling also has a positive effect on soil structure and soil life. Reducing cultivation intensity and dispensing with primary tillage conserves the composition and pore structure of the soil as far as possible. Moreover, it improves the water balance and increases in the load-bearing capacity of the soil. Another advantage is that organic matter and harvest residues remain on the surface. This prevents soil erosion by retarding the effects of wind and water and protects the soil from drying out.

The advantages of mulch drilling at a glance

- Encouraging soil life

- Preventing soil erosion

- Improving soil structure

- Increasing load-bearing capacity of the fields

- Reducing water losses

- Saving costs by reducing tillage work

Conservation agriculture with mulch drilling completely dispenses with primary tillage, i.e. the plough. Mulch drilling originated in the USA and Canada to prevent soil erosion. The aim is to keep straw and harvest residues on the soil surface as much as possible. The topsoil is then only loosened and not turned. In the 1970s, the concept of strip till was developed, in which only the band along the seed slot is cultivated, combining the advantages of direct drilling and minimum soil disturbance.

Stubble cultivators and disc harrows are essential for conservation agriculture. They manage to transfer the forces to the soil without completely breaking up its structure. The relatively low power requirement compared to the plough enables higher working speeds and greater output. They also enable freedom of transition between the topsoil and subsoil so that soil life is less disturbed. Shallow cultivation ensures that the harvest residues are incorporated and additional air is supplied, stimulating the microorganisms that improve decomposition. On top of that, the layer of mulch protects against erosion by dampening the force of raindrops. Because the lower layers remain undisturbed, the natural structure is also preserved. Active soil life increases the infiltration capacity of the soil.

| Universal drill technology at a glance | TERRASEM CLASSIC | TERRASEM CLASSIC FERTILIZER | TERRASEM | TERRASEM FERTILIZER | |

|---|---|---|---|---|---|

| Working width | 4 - 9 metres | 4 - 9 metres | 3 - 9 metres | 3 - 9 metres | |

| Single hopper with injector metering | x | x | |||

| Double hopper with pressurised hopper system | x | x | |||

| Disc section - shallow soil cultivation | x | x | |||

| WAVE DISC - strip-till soil cultivation | x | x | |||

| No tillage | x | x | |||

| DUAL DISC - coulter rail for mulch drilling | x | x | x | x | |

| Separate fertiliser rail with FERTILIZER PRO coulters | x | x | |||

| TEGOSEM single shoot / surface application | o | o | o | o | |

| Profiline comfort control system hydraulic control of all functions | o bis 9 metres | o bis 6 metres | o bis 9 metres | o bis 6 metres |

x standard

o optional

Interested in TERRASEM universal seeding technology?

We will be happy to contact you.

Perfect, efficient drilling

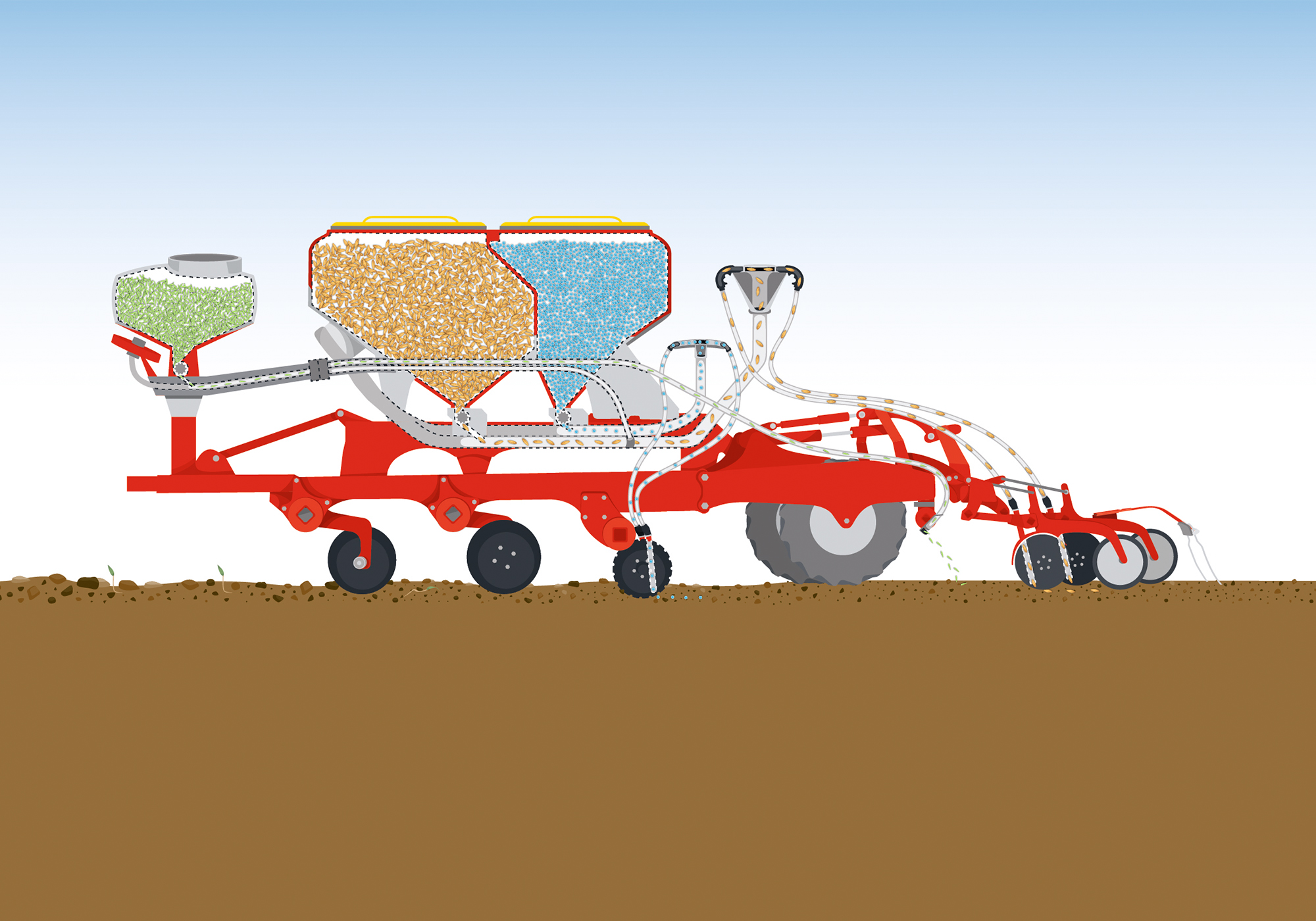

TERRASEM universal seed drill technology with its three-section configuration enables perfect mulch drilling.

Multiple advantages

The key to successful conservation tillage followed by mulch drilling is to maintain a high level of organic matter to cover the soil. A layer of mulch formed by harvest residues or a cover crop has a positive effect on the water balance and soil organisms because it is a source of nutrients. In general, planting a cover crop offers the advantage of retaining sufficient organic matter in the field even during fallow periods at the same time as providing a satisfactory mulch layer for spring sowing. On top of providing ground cover, this offers a number of other advantages. Studies have confirmed that the diversity of agronomic species in cover crop mixtures also increases the diversity of soil organisms. They enrich the organic matter in the soil, improve the soil structure and stabilise the tilth by infusing the soil with life. What is more, cover crop mixtures can have a positive effect on the nutrient balance of the soil and, depending on their composition, retain nitrogen. Some plants also have a phytosanitary effect and suppress the spread of harmful organisms.

For optimum seedbed preparation, it is important to incorporate the organic matter and mix it in well. TERRASEM universal seed drill technology integrates perfectly into any soil cultivation concept using various tillage tools so that excellent ground tracking and consistent seed placement depth are always guaranteed.

- On the high quality compact disc harrow for mulch drilling conditions you can choose between plain or scalloped concave discs.

- For water-saving loosening of the soil in strips, you can also choose the WAVE DISC.

- If you do not need tillage tools on the seed drill because the soil is already cultivated, then the TERRASEM CLASSIC series is the perfect choice.

For maximum cost effectiveness: a well-prepared seedbed thanks to optimised disc harrow intensity.

- A uniform working depth is a prerequisite for optimum germination of the seed.

- The disc harrow can also be used in heavy soils and large quantities of harvest residues. The focus here is on incorporation and crumbling.

Optimum ground tracking is an essential part of soil cultivation. The set pressure on the side frame sections as the rear roller follows the contours of the terrain ensures exact ground tracking in every position across the whole working width.

- Precise ground tracking with a consistent coulter pressure is achieved thanks to the parallel coulter linkage.

- The tillage tools are guided with precision by the packer chassis.

Top quality disc harrow

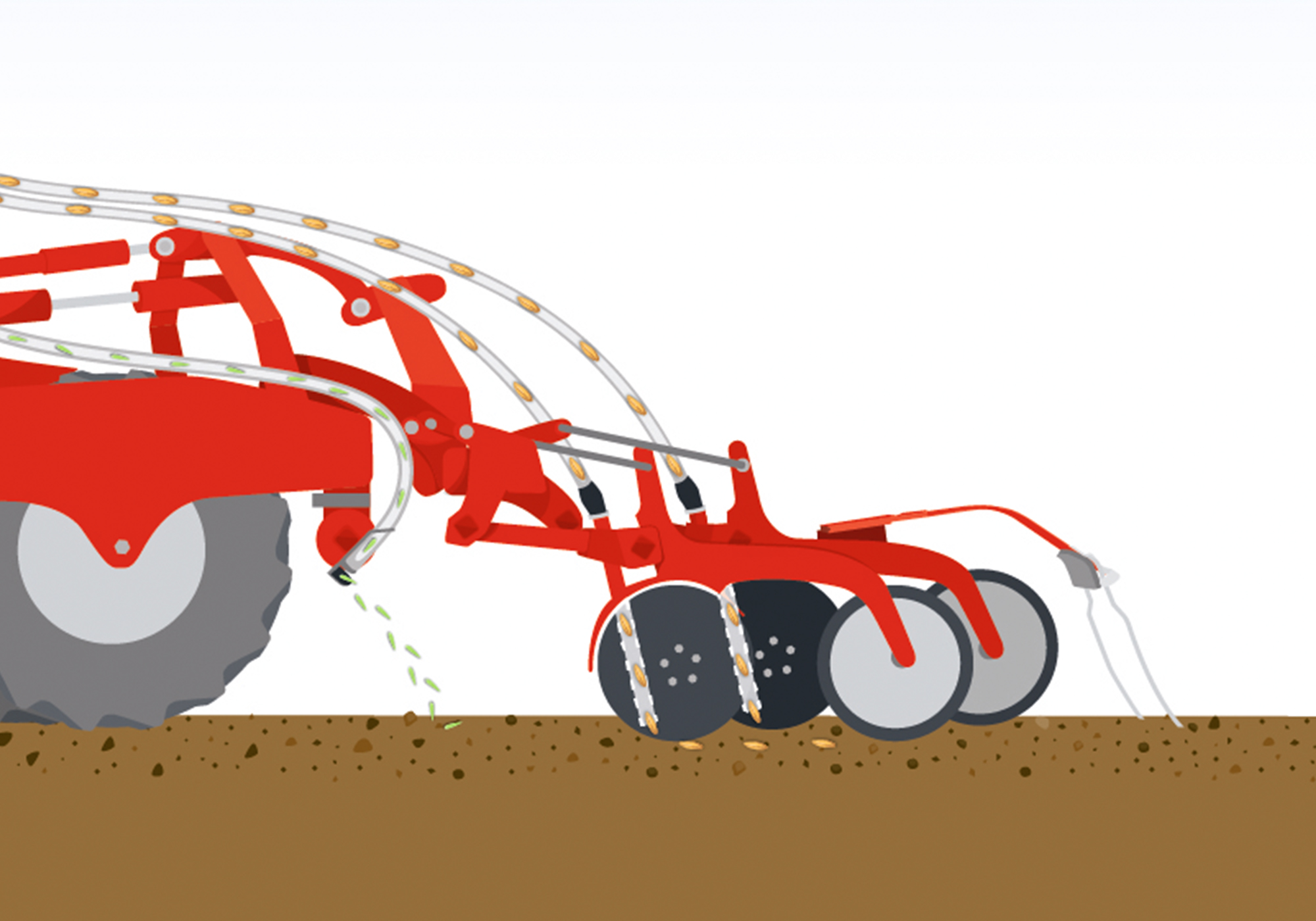

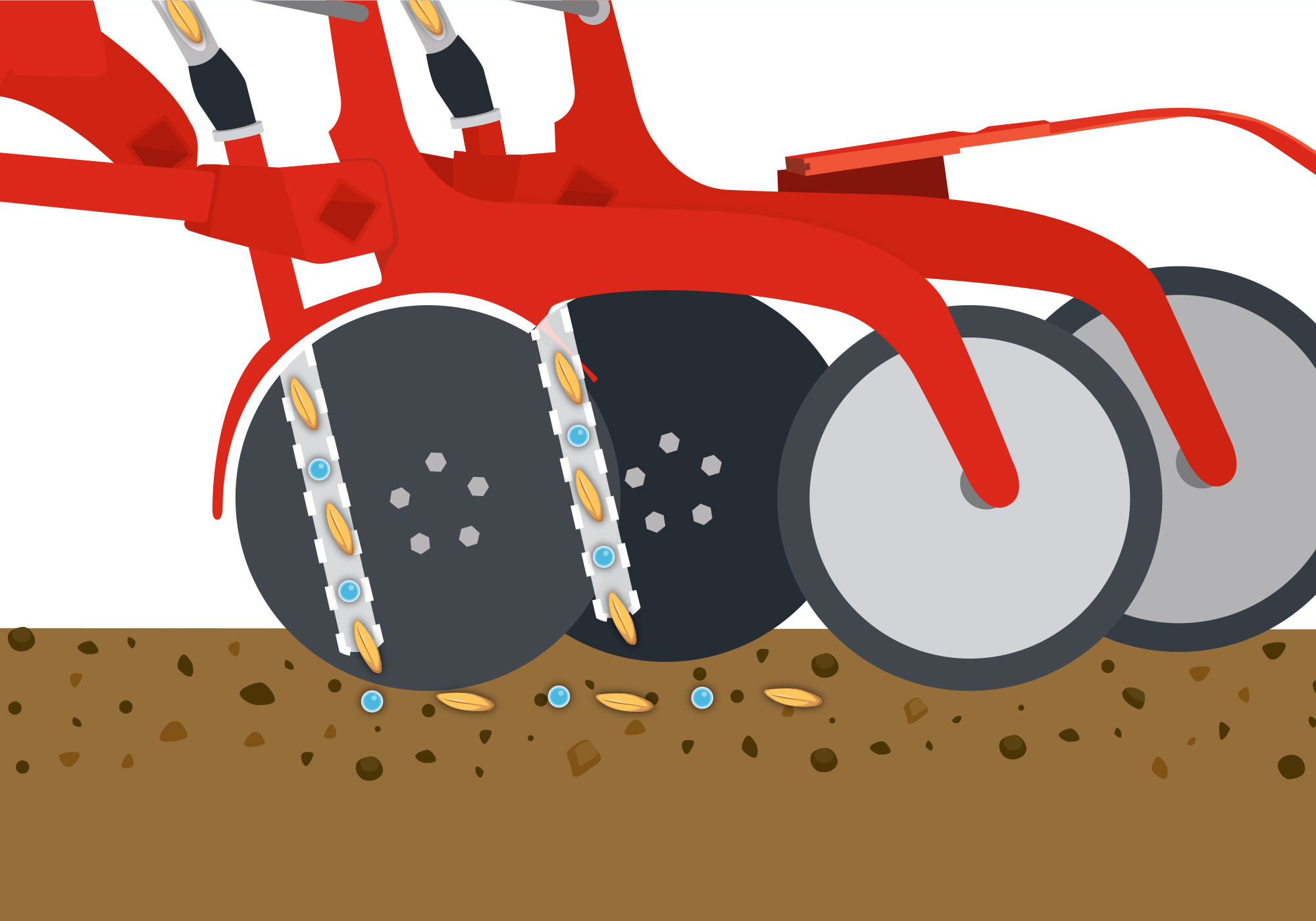

On our TERRASEM universal seed drill combinations, soil preparation is taken care of by a two-row disc harrow with plain or scalloped discs. The maintenance-free, rubber-mounted 510 mm diameter discs loosen and move the soil across the entire working width. Discs at +15° in the direction of travel and +7° vertical angle for reliable soil penetration to create an optimum seedbed with fine-structured soil at seed slot level. Large volumes of harvest residues are mixed with the soil and, at the same time, the threat of weeds is reduced.

The new configuration of the tillage tools ensures that the machine works one hundred percent in a straight line. The disc harrow as well as the fertiliser coulters (FERTILIZER machine) and seed coulters are mounted in an X configuration.

A central additional WAVE DISC in the rear section of the discs guarantees full-surface movement.

WAVE DISC – for minimum tillage

In dry regions or in humid areas, all the WAVE DISC system's advantages come into play to make it the perfect example for reduced soil cultivation while maintaining yield. Very much in the style of min-till, using a strip-till approach moves the soil in strips.

The PÖTTINGER WAVE DISC system is ideal for difficult soil conditions that require reduced tillage. The key to correct seed placement is the correct working depth.

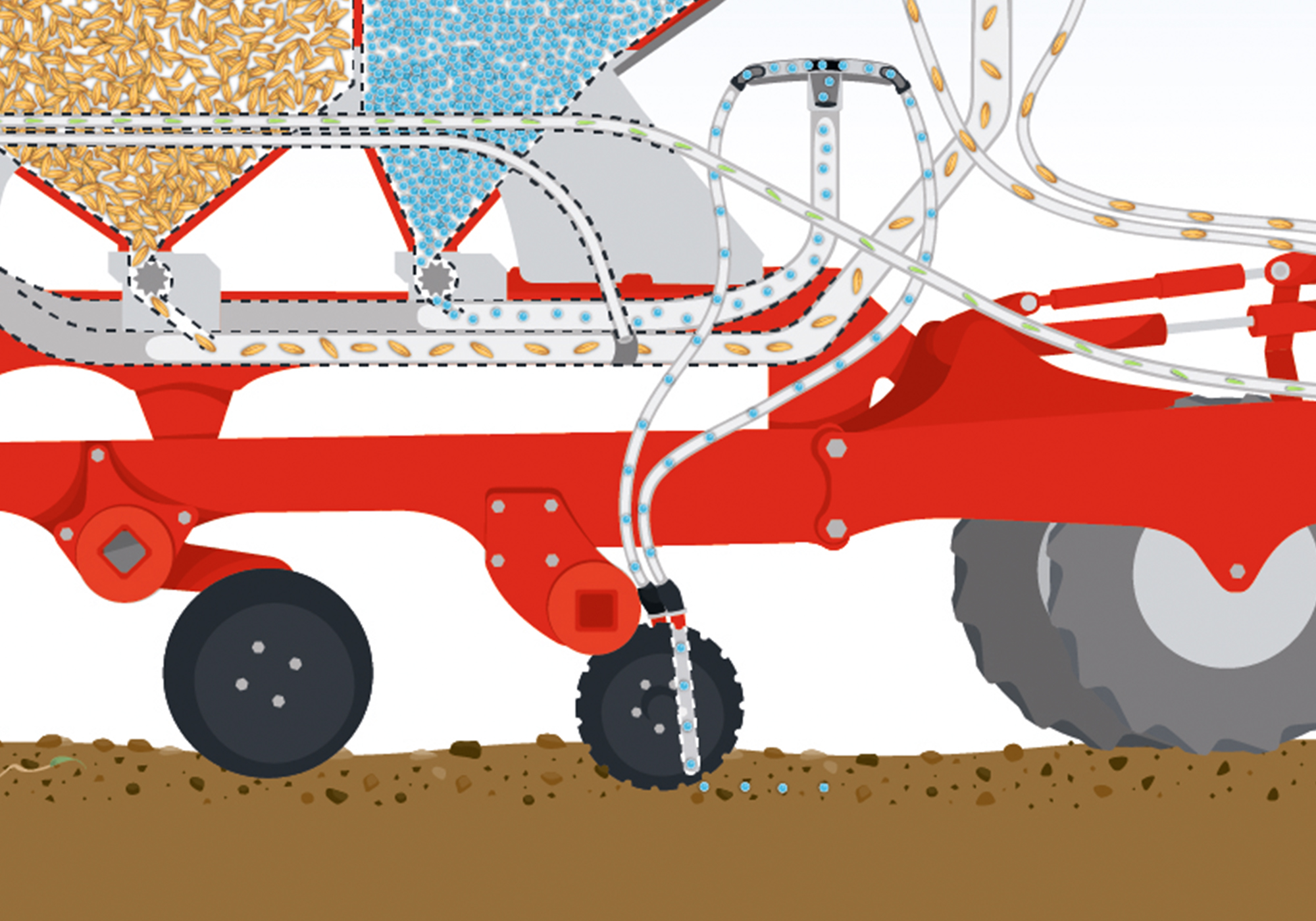

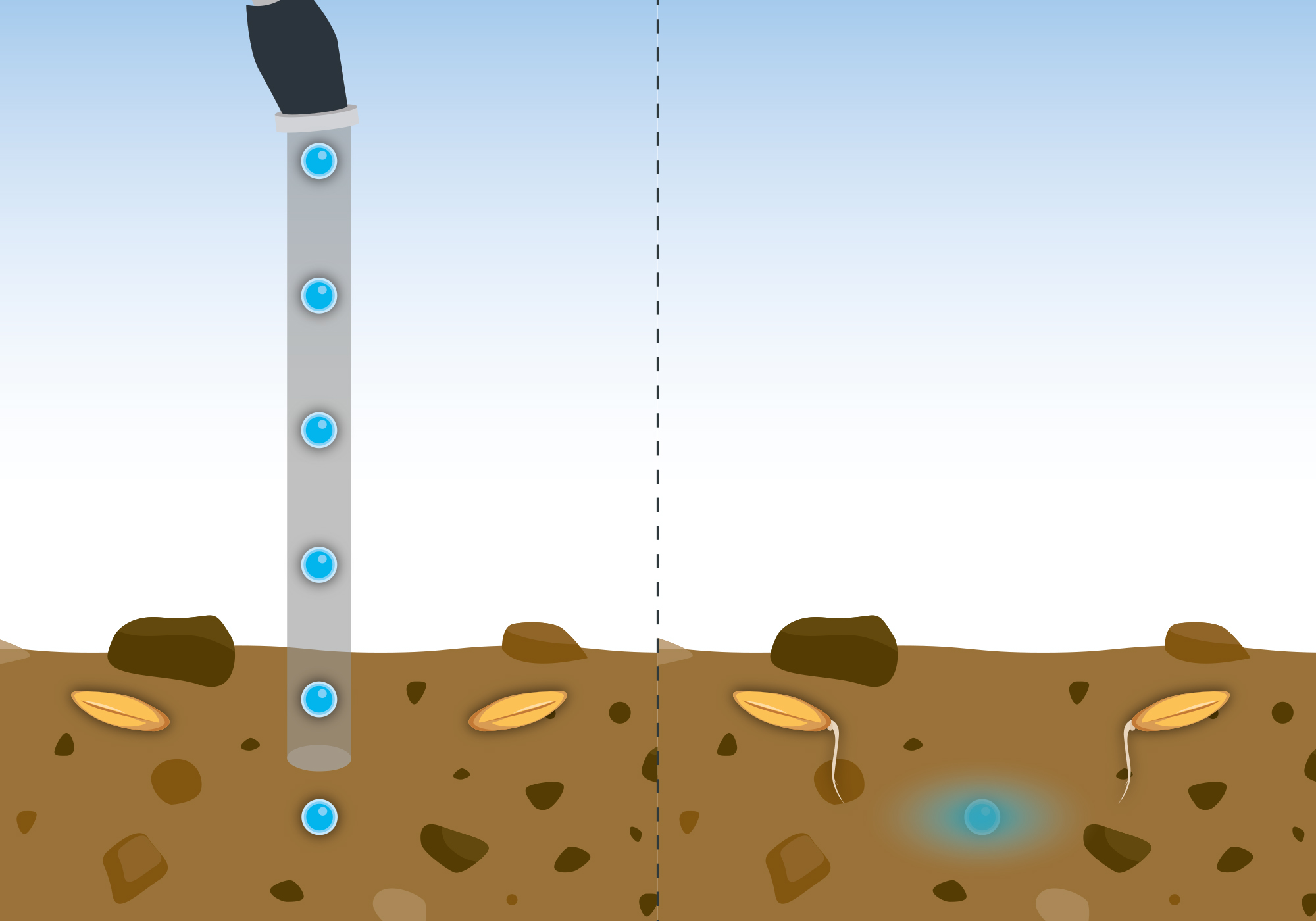

The WAVE DISC cultivates the soil in water-saving strips: only the region either side of the seed slot approx. 45 mm wide is worked. The rest of the surface remains untouched - the residual moisture in the strips in between helps the seed to germinate.

The working depth is infinitely-variable set by a hydraulic system on the WAVE DISC system. Additional WAVE DISCs behind the tractor wheels can be set individually to the seed depth and the depth of the tractor wheel marks.

The maintenance-free WAVE DISCs have a diameter of 510 mm and are available with row spacings of 12.5 cm or 16.7 cm. A row spacing of 16.7 cm is recommended for regions with extreme soil conditions. The wider row spacing improves the crop microclimate which can give plants an advantage against harmful organisms. The way the WAVE DISC works is perfect for processing frost heave and incorporating winter cover crops, but cannot be used for classic direct sowing.

Consistent yields with the mulch drilling method

Extreme weather events are becoming ever more frequent, and the challenge they present to agriculture means that conventional farming methods are increasingly reaching their limits in coping with longer periods of drought followed by heavy rain. With this scenario in mind, a good layer of mulch offers the advantage of lowering the temperature of the soil, even in direct sunlight. If the soil temperature is below 40° Celsius it can maintain soil life in its uppermost layers and also absorb water. In spring, this mulch layer can also become a challenge, because the soil warms up less quickly, dries out more slowly, and mineralisation starts later. Direct fertilisation offers an opportunity to provide young plants with sufficient nutrients right from the start to support this delicate phase of growth.

TERRASEM universal seed drill technology enables multiple application variants and precision direct fertilisation thanks to the dedicated FERTILIZER PRO fertiliser coulters. In addition to direct fertilisation using the double shoot method, it is also possible to apply seed and fertiliser at the same time using the single shoot method, or to combine the single shoot and double shoot methods in the double shoot mix. This sees the FERTILIZER PRO fertiliser coulters apply fertiliser between the rows, while a seed and fertiliser mix is placed in the seed slot using the single shoot method. In addition, a third component can be applied to the soil surface by the TEGOSEM seeding unit using baffle plates. This setup is ideal for sowing companion crops or distributing slug pellets.

Multiple sowing options

With the TEGOSEM 500 flexible hopper additional components can to be added to the mixture sown using the TERRASEM series. Space-saving, easily accessible using the loading platform, mounted in front of the seed hopper, the pneumatic sowing unit covers a wide range of applications.

- Companion crop (such as grass) sown at the same time as drilled crop

- Fertiliser or micro granules can be applied directly by the metering system as contact banding in a single shoot process

- Seed distribution is carried out pneumatically by surface application or directly by the TERRASEM metering unit into the seed coulter.

- On top of applying seed and fertiliser using the seed and fertiliser coulters, TEGOSEM can be used to apply a further component

Direct fertilisation or second type of seed with the FERTILIZER PRO fertiliser coulter

Fertiliser or a second type of seed is applied on TERRASEM FERTILIZER universal seed drills using the maintenance-free PRO single-disc fertiliser coulter. Fertiliser is applied behind the disc harrow using these coulters and placed between two seed rows as mid-row banding.

- The FERTILIZER PRO single-disc fertiliser coulters place a fertiliser deposit between the seed rows to supply nutrients to the roots.

- Precision placement saves fertiliser, minimises unproductive losses and promotes faster development of the root mass for optimum yield.

- The placement depth of fertiliser and seed can be set independently of each other.

Agriculture 4.0

The yield capacity of our soils is influenced by many factors, where morphology and location are just as important as cultivation. Because the site-specific characteristics can also vary within each field, this results in a detailed patchwork structure. Generally, potential yield is measured as an average figure, but this can lead to the full potential not being achieved, especially in fields where the agronomic characteristics are varied. With the help of application maps, fields can be subdivided into different zones to detail the requirements of the soil and crop plants. Application maps can be used for the site-specific implementation of processes that can be precisely tailored to the needs of the soil and the plants. This means that seed material and fertiliser can be applied more effectively to save resources. Especially when mulch drilling, the reduced tillage can lead to reduced nutrient availability. By using application maps, the best combination of resources can be found to match the nutrient supply, yield and soil type.

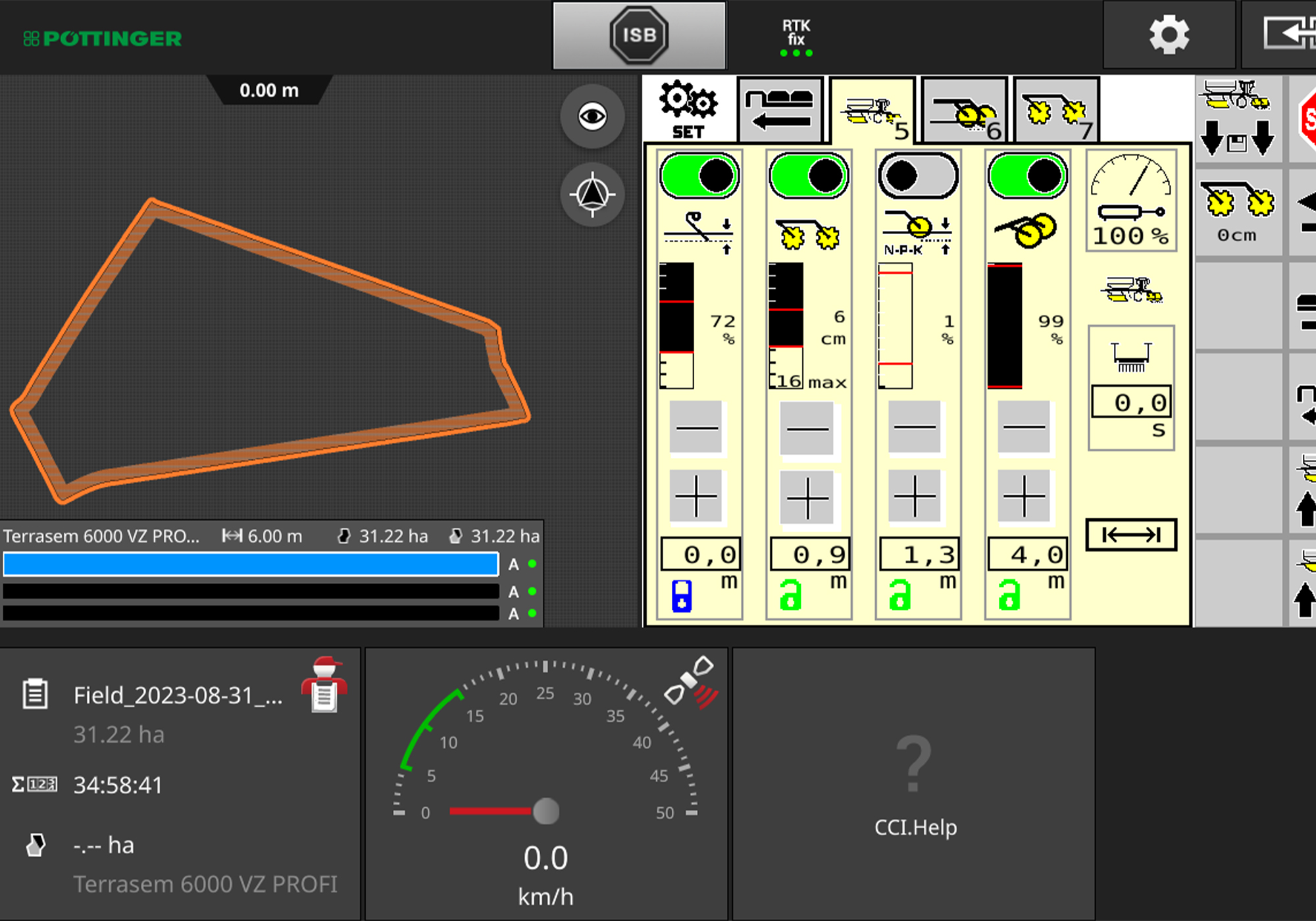

The TERRASEM offers the option of using two application maps with the Profiline comfort control system. Profiline is the comfort control system that covers all the hydraulic functions of a TERRASEM. The machines are supplied with oil by the tractor's load sensing connection, and all movements are controlled electro-hydraulically via a hydraulic block. The machine is operated by pressing a button on the control terminal or automatically by the task controller using Section Control and Variable Rate Control. This allows the working depth of the disc harrow and the coulters to be adjusted precisely. Thanks to the unique hydraulic control system, a pressure of 150 kg can be applied to the coulter rail to enable reliable seed placement during mulch drilling.

Convenient operation

While the machines can be operated manually using an ISOBUS capable terminal, their functions can also be automated using Section Control and Variable Rate Control in connection with ISOBUS. All the tillage tools and coulters are positioned automatically and precisely. The fan speed and coulter pressure are controlled automatically.

Task Controller Geo

Enabling Task Controller Geo and Section Control means that application maps can be used to operate the machine. The working depth of the disc harrow, coulter pressure and seed and fertiliser rates are then controlled automatically on a site-specific basis. This allows you to use your machines efficiently and save valuable resources.

During operation, the tools can be precisely adjusted to the site specific conditions.

Independent of Section Control, the lifting and lowering sequences can also be set based on time or distance travelled. It is also possible to deactivate individual tools.

Save time

The headland function stops and restarts the machine precisely at the headland. Without a task controller, this function is controlled at the touch of a button. With a task controller, lifting and lowering is done automatically using the TC-GEO/TC-SC signals.

The intelligent control system allows the vertical travel during lifting to be limited because shorter lifting and lowering times mean it takes less time to turn round.

Sensor monitoring enables the machine to fold and unfold automatically.

All scenarios covered with TERRASEM universal seed drill technology

DUAL DISC coulters enable PÖTTINGER machines to deliver perfect working results even with high volumes of organic residues. That is how PÖTTINGER seed drill technology achieves perfect mulch drilling.

Pneumatic universal seeding technology CLASSIC

Pneumatic universal seeding technology

TERRASEM Universal seed drill combinations

Equipped with a double-row disc harrow or WAVE DISCs, this universal seed drill combines seedbed preparation and sowing with optimum ground tracking.With working widths of up to nine metres and a seed hopper capacity of up to 5,600 litres, the machine can cover a large area.

TERRASEM FERTILIZER Universal seed drill combinations

This universal seed drill combination with a partitioned pressurised hopper system enables drilling and direct fertilisation in a single pass. The dedicated FERTILIZER PRO fertiliser coulters allow the fertiliser to be reliably placed between the seed rows. Combined with the tillage tools needed for seedbed preparation, the TERRASEM V D Z provides the basis for harvesting the highest yield.

Feedback from our customers

"Optimal soil cultivation and no crabbing"

"We have soils that vary a lot, from light to heavy. We sow most of the crops using min-till mulch drilling. That's why we decided to go for the TERRSEM V 4000 D. The strength of this machine lies in the X configuration of the disc harrow. As a result, there is absolutely no sideways pull and it cultivates the soil perfectly."

Piotr Szymanski

Farmer

Dobropole | Poland

"A versatile machine"

"The FERTILIZER equipment is the big advantage that I was looking for. It makes the machine very versatile and is perfect for my farm business. The working results are always very impressive. And above all, the number of hoppers in combination with the TEGOSEM allows me to carry out multiple applications. That was exactly what I was looking for to reduce the number of passes. This is a very important aspect, especially in terms of my contracting business."

Jean-Michel Protain

farmer and contractor

Isse, Marne | France

"Conserving the water in the ground"

"We farm 250 hectares on our own land and drill 700 hectares for third parties as a contractor. We use a TERRASEM C6 WAVE DISC, so we are very flexible in terms of different site conditions. In spring weather conditions, more homogeneous germination is achieved on loam soils. With the WAVE DISC system we conserve the water in the soil. What is more, herbicides work better because the crop protection film remains on the areas of the soil surface that are left intact."

Florent Earl Cadieu

Farmer

Charnizay | Indre-et-Loire | France

"Reliable and easy to use"

"We have two TERRASEM seed drills in operation. Because we farm more than 14,000 hectares, it is important to us that the machine is easy to operate and reliable. With the latest generation of TERRASEM, all the settings are done conveniently using the terminal so you only need to leave the cab for calibration. All the parameters are displayed on the screen and can be adjusted in real time. Sowing quality is consistent and there are two additional options for applying fertiliser, which is very important to us in the current environment."

Igor Kunitskyi

Farm Manager DP Agrofirma Luga-Nova

Volyn Oblast | Ukraine