Greatest operational flexibility

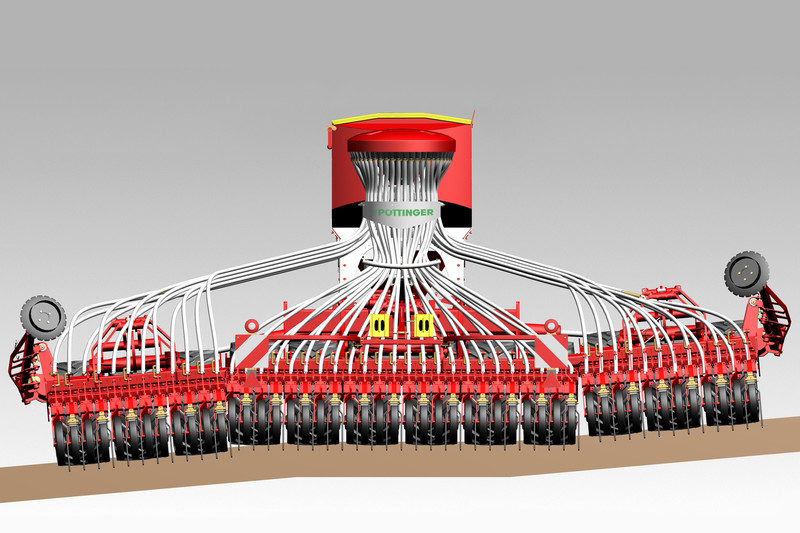

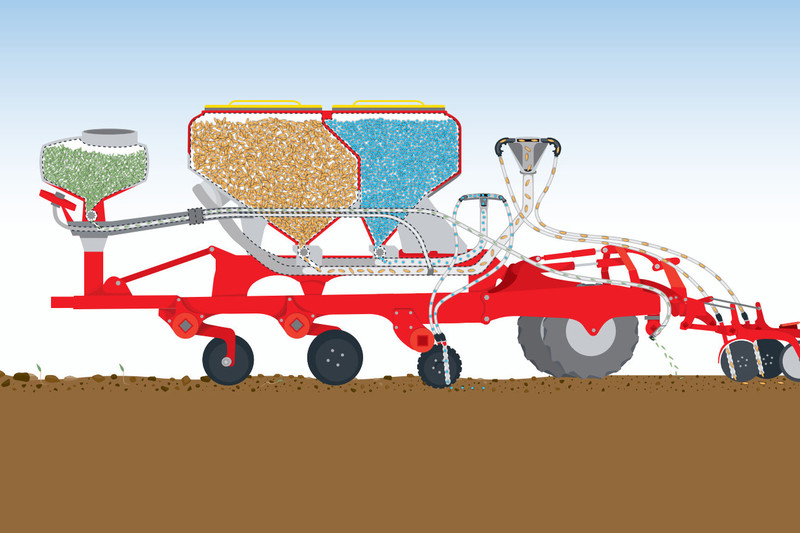

In addition to optimum soil and weather conditions, choosing the right seed drill technology is essential for perfect seed emergence. PÖTTINGER's TERRASEM universal seed drill technology combines tillage, consolidation and drilling in a single machine: the perfect combination of high output, excellent reliability and precision seed placement to meet your requirements.

In addition to optimum soil and weather conditions, choosing the right seed drill technology is essential for perfect seed emergence. PÖTTINGER's TERRASEM universal seed drill technology combines tillage, consolidation and drilling in a single machine: the perfect combination of high output, excellent reliability and precision seed placement to meet your requirements.

| TERRASEM 3000 D Z | |||||

|---|---|---|---|---|---|

| Configurate | |||||

| Working width | 3 m | ||||

| Row spacing | 12,5 16,7 cm | ||||

| Power requirement | 135 HP | ||||

| Transport width | 3 m | ||||

| Transport height | 2,8 m | ||||

| Number of rows | 24 18 pcs. | ||||

| Disc diameter | 380 mm | ||||

| Coulter spacing (Front to rear) | 32 cm | ||||

| Coulter pressure (Maximum) | 40 - 120 kg | ||||

| Press wheel diameter | 380 mm | ||||

| No. of centre press wheels | 6 pcs. | ||||

| Volume of combo tank | 4200 l | ||||

| Partition for combo tank | 60:40 | ||||

| Number of fertiliser coulters | 12 9 pcs. | ||||

| Row spacing of fertiliser coulters | 25 33 cm | ||||

| Metering unit drive | Electric | ||||

| Min. oil flow req. for fan | 50 l | ||||

| Filling opening | 2 x (104 x 131) cm |

| Working width | 3 m |

| Row spacing | 12,5 16,7 cm |

| Power requirement | 135 HP |

| Transport width | 3 m |

| Transport height | 2,8 m |

| Number of rows | 24 18 pcs. |

| Disc diameter | 380 mm |

| Coulter spacing (Front to rear) | 32 cm |

| Coulter pressure (Maximum) | 40 - 120 kg |

| Press wheel diameter | 380 mm |

| No. of centre press wheels | 6 pcs. |

| Volume of combo tank | 4200 l |

| Partition for combo tank | 60:40 |

| Number of fertiliser coulters | 12 9 pcs. |

| Row spacing of fertiliser coulters | 25 33 cm |

| Metering unit drive | Electric |

| Min. oil flow req. for fan | 50 l |

| Filling opening | 2 x (104 x 131) cm |

| TERRASEM V 4000 D Z | TERRASEM V 6000 D Z | TERRASEM V 8000 D Z | TERRASEM V 9000 D Z | ||

|---|---|---|---|---|---|

| Configurate | Configurate | Configurate | Configurate | ||

| Working width | 4 m | 6 m | 8 m | 9 m | |

| Row spacing | 12,5 16,7 cm | 12,5 16,7 cm | 12,5 16,7 cm | 12,5 16,7 cm | |

| Power requirement | 160 HP | 230 HP | 280 HP | 330 HP | |

| Transport width | 3 m | 3 m | 3 m | 3 m | |

| Transport height | 2,8 m | 3 m | 3,98 m | 4,5 m | |

| Number of rows | 32 24 pcs. | 48 36 pcs. | 64 48 pcs. | 72 54 pcs. | |

| Disc diameter | 380 mm | 380 mm | 380 mm | 380 mm | |

| Coulter spacing (Front to rear) | 32 cm | 32 cm | 32 cm | 32 cm | |

| Coulter pressure (Maximum) | 40 - 120 kg | 40 - 120 kg | 40 - 120 kg | 40 - 120 kg | |

| Press wheel diameter | 380 mm | 380 mm | 380 mm | 380 mm | |

| No. of centre press wheels | 8 pcs. | 12 pcs. | 16 pcs. | 18 pcs. | |

| Volume of combo tank | 4200 l | 4200 l | 5600 l | 5600 l | |

| Partition for combo tank | 60:40 | 60:40 | 60:40 | 60:40 | |

| Number of fertiliser coulters | 16 12 pcs. | 24 18 pcs. | 32 24 pcs. | 36 27 pcs. | |

| Row spacing of fertiliser coulters | 25 33 cm | 25 33 cm | 25 33 cm | 25 33 cm | |

| Metering unit drive | Electric | Electric | Electric | Electric | |

| Min. oil flow req. for fan | 50 l | 50 l | 80 l | 80 l |

| Working width | 4 m |

| Row spacing | 12,5 16,7 cm |

| Power requirement | 160 HP |

| Transport width | 3 m |

| Transport height | 2,8 m |

| Number of rows | 32 24 pcs. |

| Disc diameter | 380 mm |

| Coulter spacing (Front to rear) | 32 cm |

| Coulter pressure (Maximum) | 40 - 120 kg |

| Press wheel diameter | 380 mm |

| No. of centre press wheels | 8 pcs. |

| Volume of combo tank | 4200 l |

| Partition for combo tank | 60:40 |

| Number of fertiliser coulters | 16 12 pcs. |

| Row spacing of fertiliser coulters | 25 33 cm |

| Metering unit drive | Electric |

| Min. oil flow req. for fan | 50 l |

| Working width | 6 m |

| Row spacing | 12,5 16,7 cm |

| Power requirement | 230 HP |

| Transport width | 3 m |

| Transport height | 3 m |

| Number of rows | 48 36 pcs. |

| Disc diameter | 380 mm |

| Coulter spacing (Front to rear) | 32 cm |

| Coulter pressure (Maximum) | 40 - 120 kg |

| Press wheel diameter | 380 mm |

| No. of centre press wheels | 12 pcs. |

| Volume of combo tank | 4200 l |

| Partition for combo tank | 60:40 |

| Number of fertiliser coulters | 24 18 pcs. |

| Row spacing of fertiliser coulters | 25 33 cm |

| Metering unit drive | Electric |

| Min. oil flow req. for fan | 50 l |

| Filling opening | 2 x (104 x 131) cm |

| Working width | 8 m |

| Row spacing | 12,5 16,7 cm |

| Power requirement | 280 HP |

| Transport width | 3 m |

| Transport height | 3,98 m |

| Number of rows | 64 48 pcs. |

| Disc diameter | 380 mm |

| Coulter spacing (Front to rear) | 32 cm |

| Coulter pressure (Maximum) | 40 - 120 kg |

| Press wheel diameter | 380 mm |

| No. of centre press wheels | 16 pcs. |

| Volume of combo tank | 5600 l |

| Partition for combo tank | 60:40 |

| Number of fertiliser coulters | 32 24 pcs. |

| Row spacing of fertiliser coulters | 25 33 cm |

| Metering unit drive | Electric |

| Min. oil flow req. for fan | 80 l |

| Filling opening | 2 x (104 x 131) cm |

| Working width | 9 m |

| Row spacing | 12,5 16,7 cm |

| Power requirement | 330 HP |

| Transport width | 3 m |

| Transport height | 4,5 m |

| Number of rows | 72 54 pcs. |

| Disc diameter | 380 mm |

| Coulter spacing (Front to rear) | 32 cm |

| Coulter pressure (Maximum) | 40 - 120 kg |

| Press wheel diameter | 380 mm |

| No. of centre press wheels | 18 pcs. |

| Volume of combo tank | 5600 l |

| Partition for combo tank | 60:40 |

| Number of fertiliser coulters | 36 27 pcs. |

| Row spacing of fertiliser coulters | 25 33 cm |

| Metering unit drive | Electric |

| Min. oil flow req. for fan | 80 l |

| Filling opening | 2 x (104 x 131) cm |

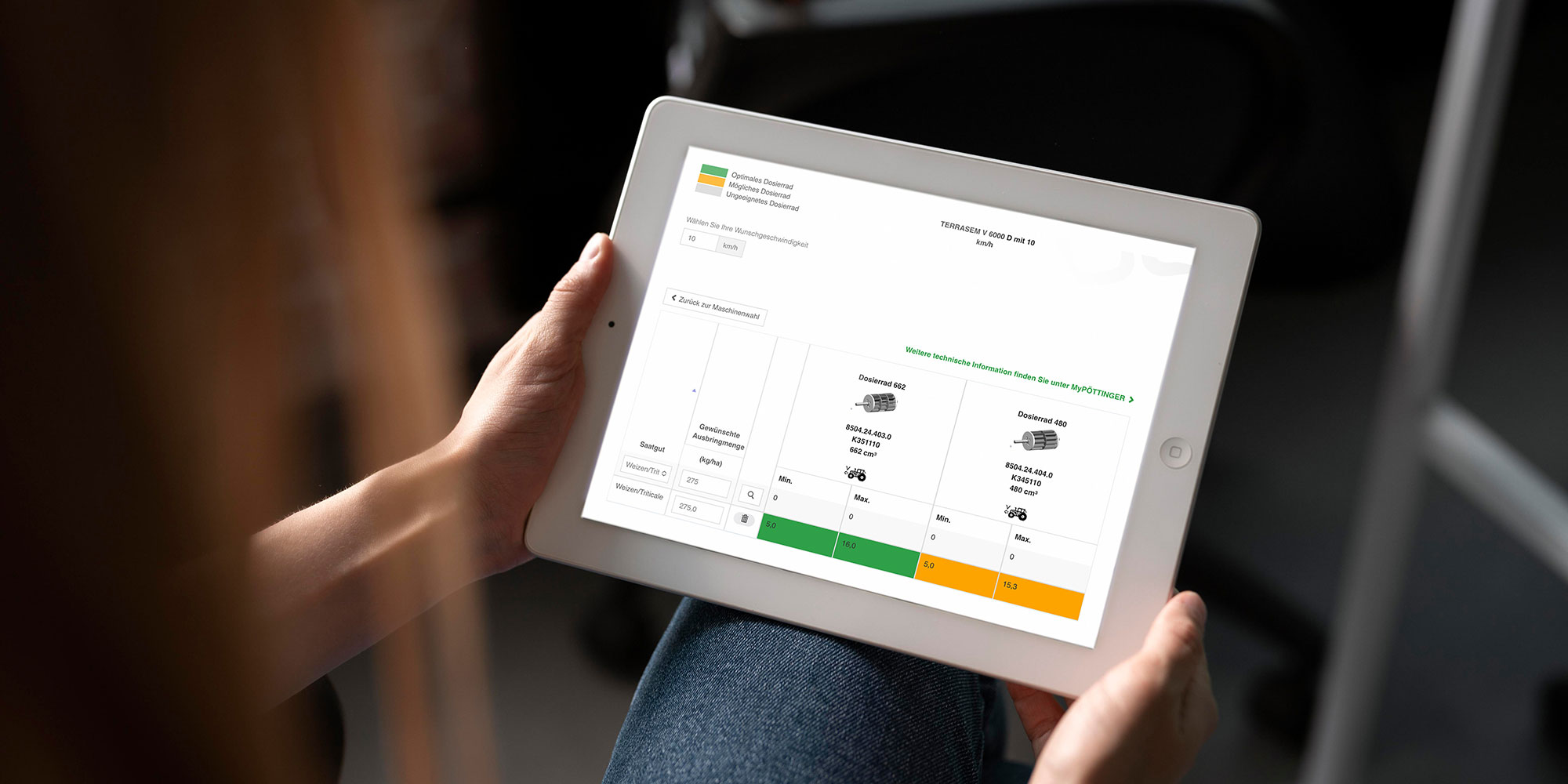

Choose the right metering wheel for your seed material simply by using METERING WHEEL ASSIST on your smartphone, tablet or PC. Get the new app from the App Store now (for iOS operating systems).

To the METERING WHEEL ASSIST app: https://www.poettinger.at/metering-wheel-assist/

To the iOS app: https://itunes.apple.com/de/app/p%C3%B6tsem/id1434048370?mt=8

To set up the optimal tramline system, you need to synchronise your machinery. TRAMLINE ASSIST helps you to do this. When choosing your seed drill, parameters such as the working width of your crop care machines, track and tyre widths are critical for optimising tramlining. TRAMLINE ASSIST identifies the tramline rhythm for you, the position of the tramline rows, and the number of rows that need to be switched off.