The all-rounder among the seed drills

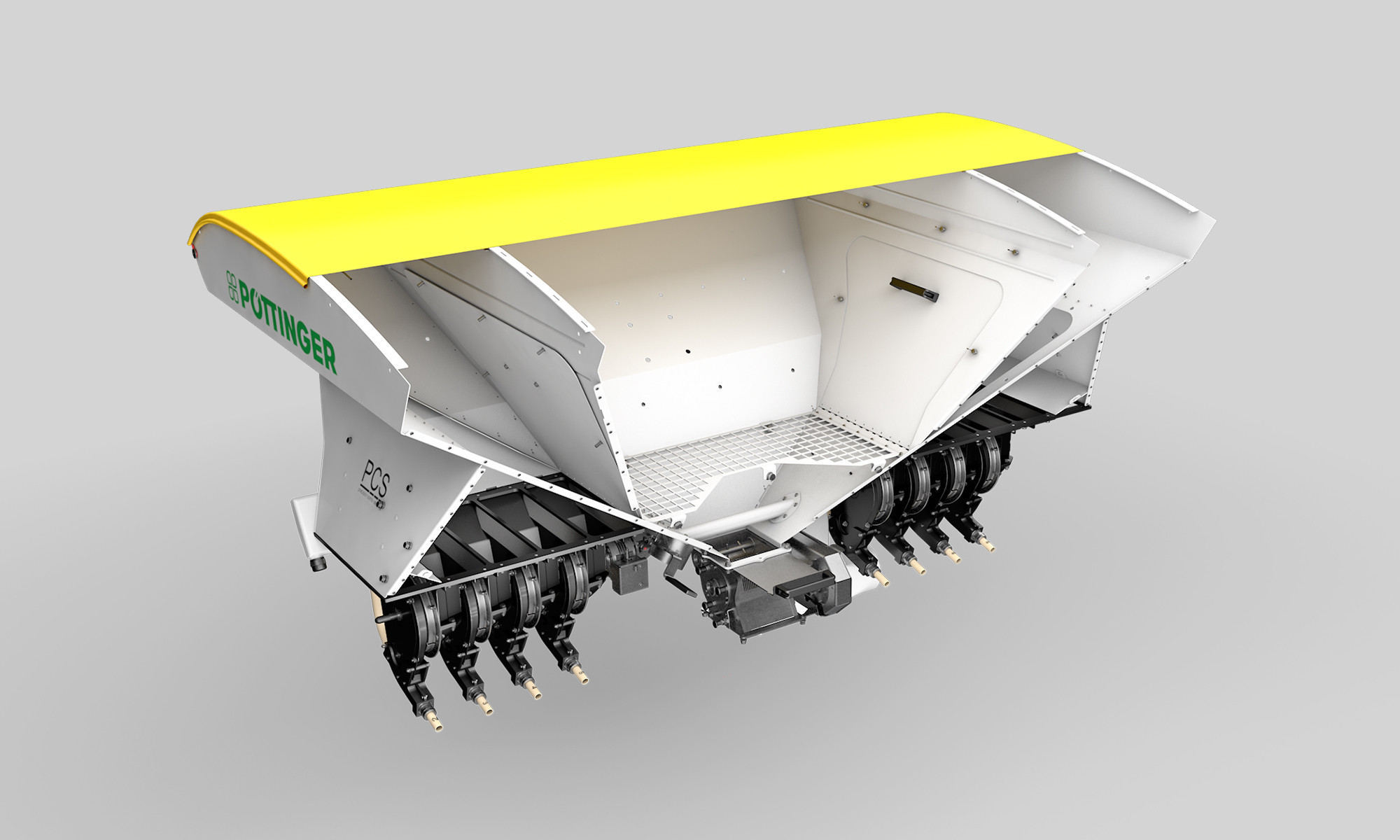

Efficiency with every seed. The pneumatic AEROSEM A implement-mounted seed drill is unique in combining maximum versatility with the highest output. Perfect placement of the seed is always the most important factor, this is made possible by a precision universal metering system and robust coulters. In addition to sowing cereals, this implement-mounted machine concept makes it possible to sow maize using precision seed drill technology.

PRECISION COMBI SEEDING system for reliable maize seed separation

Matched to your farming requirements

The pneumatic AEROSEM A implement-mounted seed drill can be equipped with either single disc coulters or DUAL DISC coulters. The standard hopper with injector metering system is capable of carrying up to 1850 litres of seed material with the optional hopper extension. PRECISION COMBI SEEDING can be added to the standard hopper. This features separator elements that enable individual maize seeds to be sown. The hopper is partitioned into three sections to provide the option of applying fertiliser using an injector metering system. The seed is placed in the seed slot by modified DUAL DISC coulters.

Precision maize seed placement using DUAL DISC coulters

Maximum flexibility

The seed drills equipped with ISOBUS and the INTELLIGENT DISTRIBUTION SYSTEM tick all the boxes in terms of metering accuracy. In addition to freely selectable tramline switching, part-width switching of the machine is also possible. This means that the resources used are applied at site-specific flowrates and are flexibly adapted to the task in hand.

For optimum reliability and maximum flexibility, the row widths can be extended using distribution head inserts, regardless of the IDS equipment level of the distribution head. The conveniently interchangeable inserts are available for different row widths and ensure that the seed is guided gently to the available coulter pipes.

Reliable seed placement even in the toughest operating conditions

One hopper for all jobs

The AEROSEM ADD seed drill offers the option of adding separator elements to the hopper designed for drilling. This means that in addition to drilling, maize seeds can also be precision sown cost effectively.

On top of the proven features of the standard hopper, seed drills equipped with PRECISION COMBI SEEDING have two partitions inside the hopper that can be easily repositioned without the need for tools using wing nuts. This allows the hopper to be divided into three sections. This frees up the two sections for the separator elements.

Two positions for many possibilities

- The standard metering system allows fertiliser to be applied on both sides of each seed row.

- Instead of row fertilisation, for example, a companion crop can also be sown for improved erosion control.

- The separator elements are positioned on the left and right of the fertiliser hopper.

- Seed material is reliably guided towards the separator elements, even with small quantities of seed, thanks to the wide, funnel-shaped outlets.

- Quick handling times for filling, emptying and seed changes.

- As standard the hopper can hold 450 litres of maize (2 x 225 l) and 800 litres of fertiliser.

- With the hopper extension there is space for 650 litres of maize (2 x 325 l) and 1,200 litres of fertiliser.

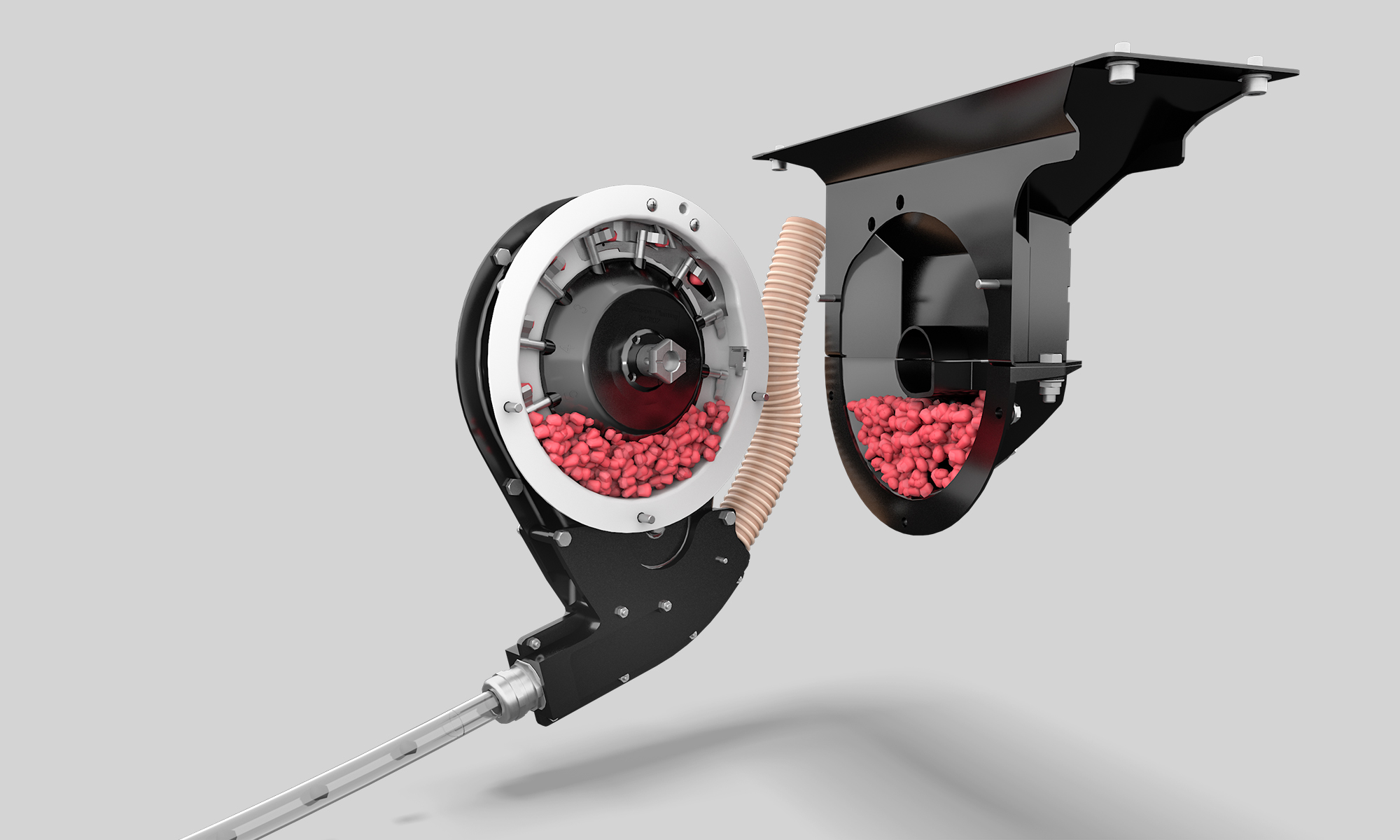

The single-seed precision metering elements are located beneath the seed hopper. This hydraulically-driven system ensures exact mechanical separation. The seeds are collected in the sump and reliably separated using adjustable singulators. At the top, each seed is transferred individually to a seed elevator.

Consistent spacing in the seed slot thanks to seed elevator

The seed elevator rotates at the same speed as the separator. The matching number of cups ensures a precise supply to the air stream. That is how consistent spacing in the seed slot is ensured.

Pneumatic seed transport

An air flap divides the air stream between the injector metering system and the PCS elements. The pressurised air system conveys the seed at precise intervals from the seed elevator to the seed coulter.

A seed flow sensor in each row indicates to the driver in real time the accuracy of seed distribution in the seed slot.

- Easy adjustment of seeds per hectare

- Monitoring seed slot distribution in each row

- Recording missing and duplicate positions

- Easy singulator adjustment depending on seed size

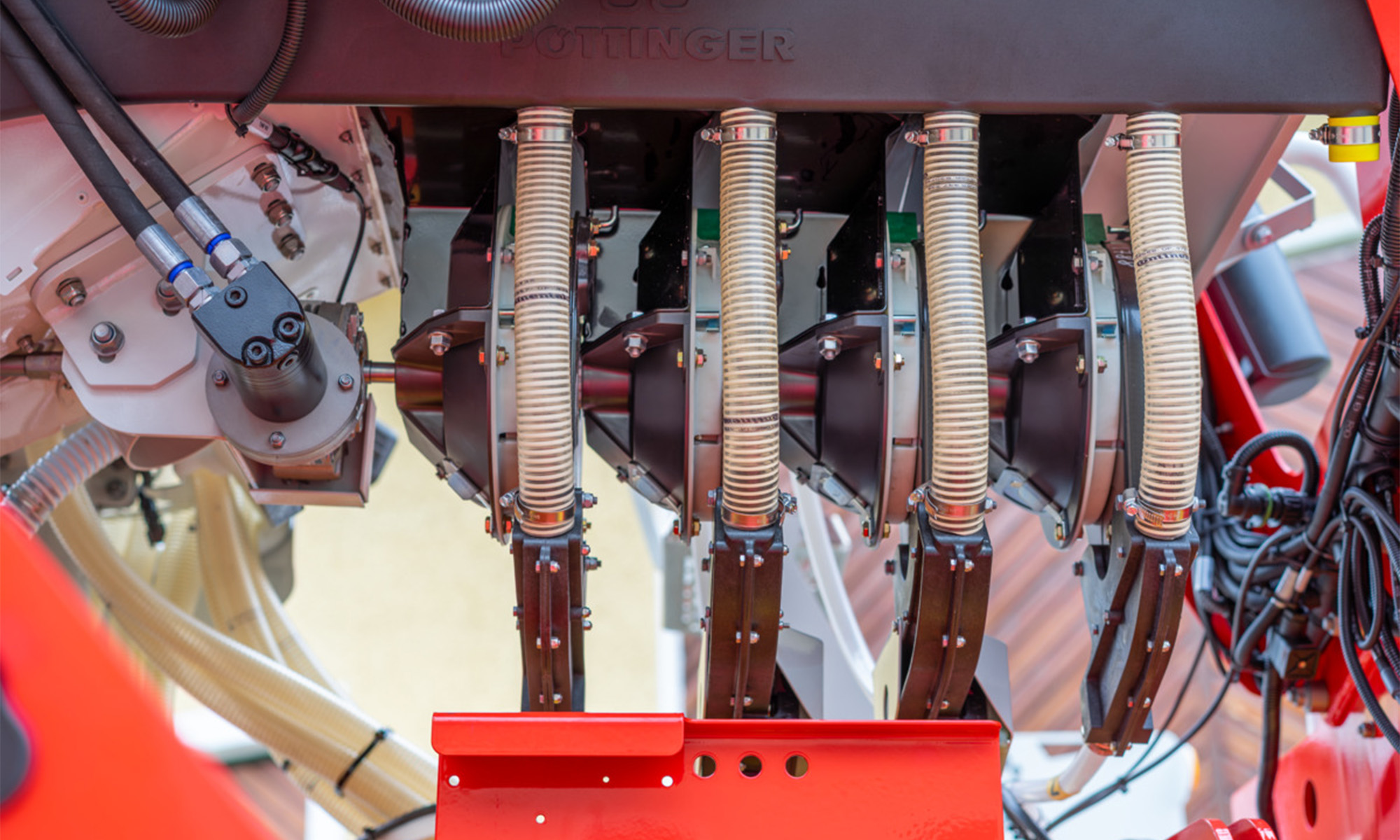

Modified DUAL DISC coulter

The optimally modified PCS coulters perfectly embed the maize seeds in the seed slot.

- Lowest drop height thanks to dedicated coulter outlet with integrated seed slot former

- Precision placement because firming roller stops seed rolling along slot

- Optimum covering of the seed with press wheel

The coulter pressure of the heavier duty PCS coulters has been increased from a maximum of 50 kg to 80 kg using coulter pressure springs. These ensure optimum soil entry even in really hard conditions.

The seed slot former for maize seeds ensures a perfect seed slot. The separate seed outlet on each PCS coulter transfers the maize seed to the firming roller at the end of the seed slot former so it has the smallest possible drop height.

Each firming roller presses the maize seed down precisely as soon as it leaves the seed slot former. The rollers are made from stainless steel and are fitted with scrapers as standard to prevent clogging. The standard 50 mm-wide press wheels provide optimum depth control of the whole PCS coulter assembly. The seed placement depth can be adjusted centrally from the side of the machine.

Precision sowing with three different row spacings

There is a choice of systems for giving our crops the best start. The AEROSEM ADD equipped with PRECISION COMBI SEEDING (PCS) offers the option of sowing individual maize seeds in addition to drilling. Thanks to its increased versatility, the AEROSEM ADD is an extremely cost effective way to sow maize.

The PCS system is available in three different versions:

- Row spacing 37.5 cm

- Row spacing 75 cm

- DUPLEX SEED with double row spacing 75 cm

On all three versions it is possible to apply fertiliser or sow a companion crop between the maize rows at the same time.

A wide choice of distributor head inserts allows fertiliser to be added to the left and right of the maize regardless of the row spacing. Additional mountings on the press wheels allow the fertiliser to be deposited deeper.

It is also possible to deposit fertiliser, soil nutrients, and biostimulants directly into the maize rows. Different distributor head inserts are provided for this purpose in order to avoid increased seed material abrasion.

Companion crop seeds, nutrients, insecticides, etc. can be applied using all of the free seed lines between the maize rows using the individual flap positions on the distributor head.

The AEORSEM A covers a wide range of applications. Equipped with the PCS system, it becomes a true all-rounder. Adaptable to match all farming requirements.