The best soil

The unique AEROSEM seed drill concept from PÖTTINGER unites high output with versatility. Perfect placement of the seed is the most important factor. We guarantee this with our precision universal metering system and ingenious, robust coulters. The front hopper system also offers the capability of sowing a mixture of seed components together at the same time.

The unique AEROSEM seed drill concept from PÖTTINGER unites high output with versatility. Perfect placement of the seed is the most important factor. We guarantee this with our precision universal metering system and ingenious, robust coulters. The front hopper system also offers the capability of sowing a mixture of seed components together at the same time.

| AEROSEM 4002 FDD | |||||

|---|---|---|---|---|---|

| Working width | 4 m | ||||

| Seed hopper volume | 1700 l | ||||

| Row spacing | 12,5 cm | ||||

| Coulter pressure (Maximum) | 50 kg | ||||

| Coulter spacing (Front to rear) | 30 cm | ||||

| Transport width | 2,75 m | ||||

| Number of rows | 32 pcs. | ||||

| Seed hopper volume optional | 2400 l | ||||

| Min. oil flow req. for fan | 40 l |

| Working width | 4 m |

| Seed hopper volume | 1700 l |

| Row spacing | 12,5 cm |

| Coulter pressure (Maximum) | 50 kg |

| Coulter spacing (Front to rear) | 30 cm |

| Transport width | 2,75 m |

| Number of rows | 32 pcs. |

| Seed hopper volume optional | 2400 l |

| Min. oil flow req. for fan | 40 l |

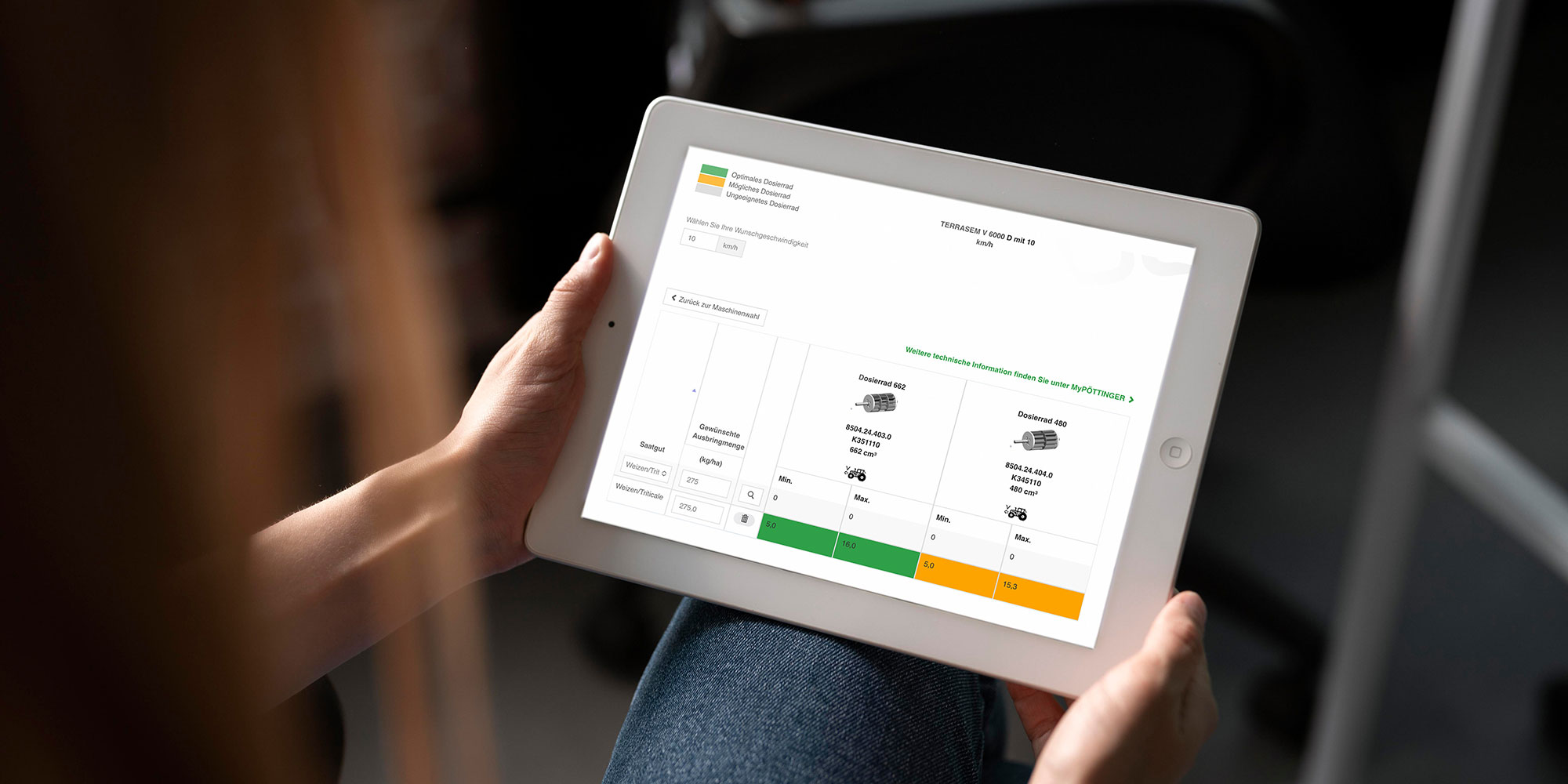

Choose the right metering wheel for your seed material simply by using METERING WHEEL ASSIST on your smartphone, tablet or PC. Get the new app from the App Store now (for iOS operating systems).

To the METERING WHEEL ASSIST app: https://www.poettinger.at/metering-wheel-assist/

To the iOS app: https://itunes.apple.com/de/app/p%C3%B6tsem/id1434048370?mt=8

To set up the optimal tramline system, you need to synchronise your machinery. TRAMLINE ASSIST helps you to do this. When choosing your seed drill, parameters such as the working width of your crop care machines, track and tyre widths are critical for optimising tramlining. TRAMLINE ASSIST identifies the tramline rhythm for you, the position of the tramline rows, and the number of rows that need to be switched off.